In Munich, the Jenoptik Optical Systems division informs about new product technologies for pulse compression gratings as well as an innovative measuring system for high-precision stack-mounted objectives.

All product images are available for downloading in the Jenoptik image database under Current Events / LASER World of PHOTONICS.

Further information on Jenoptik products can be obtained at the LASER World of PHOTONICS in Munich in hall A3 at booth 235 or at www.jenoptik.com/laser2015.

Products of the Lasers & Material Processing Division

QCW Stack with Optimized Bar Design for more Output Power

At LASER World of PHOTONICS, Jenoptik will present, for the first time, the JenLas® QCW Cool laser stack, whose key feature is an optimized bar design, enabling extremely high light output powers for various QCW applications. Depending on customer requirements, the stack is suitable for applications requiring high brilliance or high peak output power as well as for applications requiring long pulse width while providing reliable operation and efficient heat removal.

This improved stack when equipped with eight laser bars offers an optical peak power of 3,000 W for 100 ms pulses at 20 percent duty cycle. In this operation mode, reliable operations up to 15 Mshots is ensured. That makes the stack perfect for use in aesthetics.

Despite the dense arrangement of the bars, the JenLas® QCW Cool has a low thermal resistance because of the directly integrated and easy-to-use tap water cooling.

Disk laser JenLas® D2.mini 8W Quicker to Integrate

The JenLas® D2.mini with an output power of up to 8 Watt (cw) can now be integrated directly more quickly; the complete D2.mini series from Jenoptik can be combined with OEM industrial electronics or in a compact variant that has been tested in accordance with EN60601-1. Furthermore, the OEM design and low construction volume of the laser allows for easy integration into various laser treatment systems as well as miniaturization of terminal devices.

The JenLas® D2 technology from Jenoptik has proven itself as a beam source in medical technology in recent years. The green disk laser with a wavelength of 532 nanometers is used successfully particularly in ophthalmology for retinal photocoagulation but also in laser endoscopy and dermatology.

Reliable Femtosecond Laser for Continuous Use in Industry

Jenoptik has also recently started using femtosecond pulses in the automotive and consumer sector for structuring and perforation of leather. In contrast to conventional, mostly mechanical methods, the material changes on the visible side of the leather are invisible. At the same time, the inhomogeneities a natural product necessarily is subject to have no influence on the final result.

The patented combination of non-thermal femtosecond pulse removal with a highly precise sensor-controlled ablation depth guaranties that the perforation or the predetermined breaking points remain permanently invisible. At the same time, the use of Jenoptik femtosecond lasers allows for a very high process speed. This meets the strict requirements of the automobile industry and for premium products in the consumer industry.

A further major application area for femtosecond lasers is the micro-cutting of stents made of nitinol or biodegradable polymers. The manufacturing process is very demanding, as the structures being cut are extremely small and the materials lose their specific characteristics, for example such as shape memory or biodegradability, even with moderate thermal influences. With the JenLas® D2.fs and JenLas® femto 10 femtosecond lasers from Jenoptik, the stent structures can be cut at very high speed in a non-thermal way, such that the stents do not differ from the basic material in terms of their basic properties and are free of burrs – expensive post processing is not necessary. The manufacturing process therefore meets the medical and economic requirements.

The Jenoptik Laser & Material Processing division has been developing femtosecond lasers since as early as 2002. Particular attention is paid to industrial capability, reliability in 24/7 continuous use and simple system integration. In application tests and installation, customers receive support worldwide from highly qualified application engineers and service staff.

3D Laser Cutting of Plastics and Metals with Greatest Precision

Jenoptik is a competent partner not only for micro but also for macro material processing. The JENOPTIK-VOTAN® BIM 3D laser cutting system (Beam in Motion) cuts metals and plastics flexibly, quickly and cost-effectively.

The laser beam delivery of the JENOPTIK-VOTAN® BIM is integrated into the laser robot arm; the laser beam is coupled in through the robot foot. The transport fiber is therefore not moved with it in the working area, which reduces system maintenance costs considerably. Together with the laser cutting head, which weighs only five kilograms, this facilitates the high level of flexibility of the laser cutting system – even the most narrow areas are easily accessible.

The JENOPTIK-VOTAN® BIM stands out not only for its flexibility but also for its precision at the same time as having a high processing speed. With repeat accuracy of ±50 µm, the laser cutting system from Jenoptik is one of the most precise in robotic system technology. Moreover, the axis movements of the laser arm are up to 60 percent faster than current standards – the cycle times of the customer can therefore be shortened considerably.

To achieve an optimum result for the broadest range of applications, Jenoptik offers both the individual JENOPTIK-VOTAN® BIM system and other system variants based on the modular designed robot module. With the open interface for integration into a complete system concept, there are many application possibilities, for example such as a system with pick-and-place robot or a multi-robot system in which several robots work in parallel on one component and which therefore offers maximum flexibility and productivity.

A live demonstration of the 3D robot system can be seen at LASER World of PHOTONICS in Munich at booth 235 in hall A3.

News of the Optical Systems Division

Universal Wavefront Measuring System for Semiconductor Equipment Industry

When installed in the vertical position on the customer site, the new development from Jenoptik guarantees an accurate and reproducible wavefront measurement that is comparable with interferometric systems. Furthermore, image field curvature and distortion measurements as well as a pupil and field-dissolved measurement of the transmission and polarization properties of optical systems can be taken fully automatically using the measuring system. Optical systems up to a total weight of 1,000 kilograms are therefore validated within the shortest time.

In this measuring system, Jenoptik combines various measuring principles in order to be able to adapt it universally at the request of the customer. The adjustment and certification of telescopes with a high light guidance factor, high-aperture lenses and lithography lenses are therefore possible. The use of a special Shack-Hartmann sensor from Jenoptik increases the flexibility with respect to wavelengths. As such, in addition to the standard wavelengths in the semiconductor market (193 and 266 nanometers), exotic wavelengths such as 213 or 198 nanometers can also be measured with no problem.

The universal measuring system reduces costs and delivery time for customers and allows more precise and quicker adjustment of the complete system. This provides huge benefits for development of the next generation of optical lithography and inspection systems.

The project was supported by the Thüringer Aufbaubank (Thuringia Reconstruction Bank).

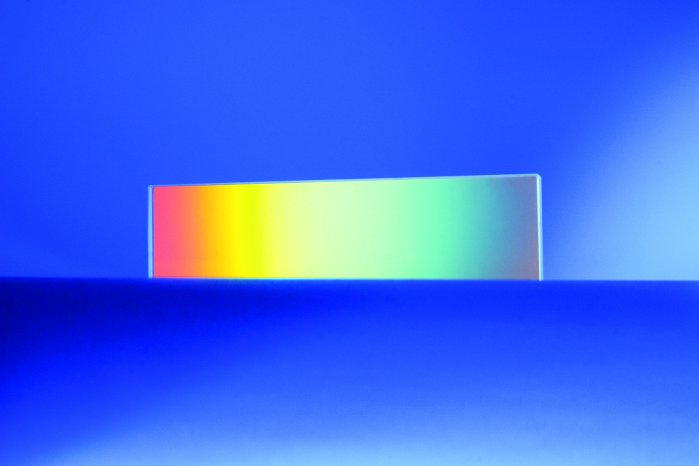

New Highly Efficient e²® Compression Gratings

The new e² gratings from Jenoptik are used primarily for pulse compression in visible to near infrared femtosecond lasers for applications in laser material processing and healthcare. For applications in the semiconductor industry, Jenoptik also offers individual, highly efficient e² gratings for the UV wavelength range.

Jenoptik is setting new standards with measured diffraction efficiencies of above 98 percent at line densities of 1,700 lines/millimeter, which can improve the wall plug efficiency for the entire laser up to 25 percent. The damage threshold of over 300 mJ/cm2 guarantees long durability. Part size and shape can be customized with dimensions up to 270 millimeters by 200 millimeters.

With line densities now reaching 3,000 lines/millimeter, compressor designs that are more compact can be realized in femtosecond lasers, allowing significantly greater dispersion compensation (pulse compression). By doubling the line density, the beam path from the compressor can be shortened by 25 percent or the dispersion compensation increased fourfold for the same compressor length.

The very high efficiency of e² gratings, developed in cooperation with the Fraunhofer Institute for Applied Optics and Precision Engineering (IOF), and the resulting performance improvements make this technology attractive for manufacturers of femtosecond lasers.

Please also visit us at our presentations during the trade fair or one of the accompanying conferences:

Ultrafast Lasers Jump to Macro Applications

LiM 2015 – Lasers in Manufacturing

Martin Griebel / Lasers & Material Processing division

June 23, 11.30-11.45 h, Room Newton1, Hall A3, 1st Floor

Analysis of positioning errors at slow tool servo machining of optical freeform and reference surfaces

EOS 2015 Conferences

Dr. Lars Dick / Optical Systems division

June 23, 16.00-18.00 h, Congress Centre, Hall B0, Ground Floor

F-Theta at Jenoptik – a holistic approach

LiM 2015 – Lasers in Manufacturing

Dr. Tim Baldsiefen / Optical Systems division

June 24, 9.45-10.00 h, Room Newton 1, Hall A3, 1st Floor

Ultrafast Thin Disk Lasers for Industrial Applications

Application Panel – Laser and Photonics in Actual Practice

Sven Poggel / Lasers & Material Processing division

June 24, 11.40-11.55 h, Forum Hall B3

Jena, June 2, 2015