Our JTAGLive Family

This easy-to-use and extremely economic board debug tool, was launched in 2009. JTAG Technologies has been in the boundary-scan business since 1993, and we've used that experience to create an all-new, low-cost tools suite accessible to every engineer and technician involved in PCB debug and test.

As hardware designers ourselves, JTAG Technologies know the pressures facing today's Electronic Engineers. Design a new product that's highly functional and meets strict cost and reliability objectives. And, of course to be sure to get prototypes up and running quickly. Underneath the skin of JTAGLive is the power of boundary-scan, capitalizing on the built-in test resources in many of the chips on the board.

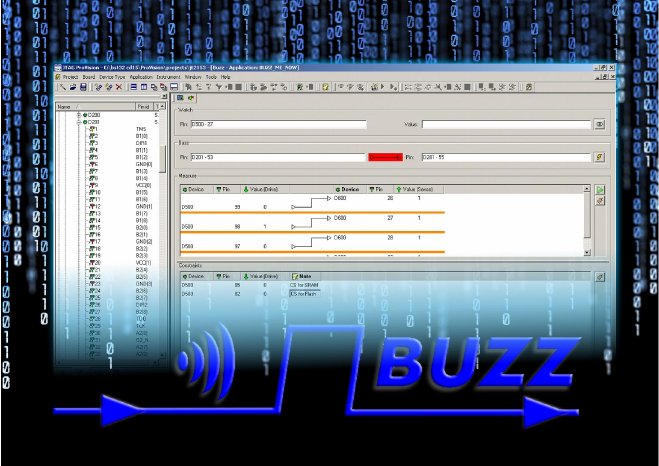

The Latest Tool from the JTAGLive Family

AutoBuzz is a totally unique new tool that effectively learns a connectivity signature of all boundary-scan parts within a design from only the BSDL models of those parts. By expanding on the seek and discover mode of BuzzPlus, AutoBuzz automatically gathers the circuit data of a known good board and then performs a full connectivity compare against the faulty circuit.

AutoBuzz supports just two simple operating modes: Learn and Compare. With AutoBuzz in Learn mode a 'known good' sample PCB is initially scanned to establish a reference connectivity map. Suspected faulty boards can then be scanned by AutoBuzz in Compare mode, and a comparison is automatically made of their connectivity maps. Differences between the two maps are highlighted to indicate possible faults such as interconnect short-circuits, open-circuits or 'stuck-at' faults.

Since the user requires no boundary-scan technical knowledge and with only a basic scan chain input needed, AutoBuzz is the perfect tool for repair and rework technicians, especially when design data is missing or incomplete.

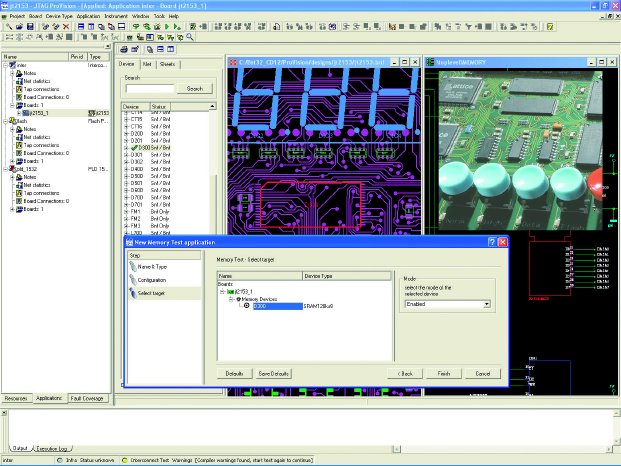

Also to Showcase : ProVision Designer Station offers complete JTAG development package - low entry price

JTAG Technologies is also showcasing a new economically-priced software and hardware system for board-level and system designers looking to benefit from a boundary-scan test and programming strategy. Boundary-scan, or JTAG, testing has remained a powerful tool for identifying assembly faults such as open- and short-circuits, missing components and damaged devices since its introduction (as IEEE Std 1149.1) in 1990. However, while boundary-scan tools have been in use for almost 20 years, the relatively high cost of 'professional' systems has meant that they largely remain in the domain of test and production engineers.

JTAG Technologies' ProVision Designer Station offers now a low entry price yet retains key features such as automatic test program generation (ATPG) for interconnections and in-system programming (ISP) for devices. It is ideal for the preparation of all boundary-scan test routines that might be used in the design environment and beyond. The tool incorporates a highly automated test program generator for interconnects that takes advantage of a library of thousands of non-boundary-scan (cluster) device models to create a safe [to execute], high-quality core test.

The rapid generation and execution of this so-called 'Interconnect Test' using the handy JT 3705/USB controller, that is included with the system, allows the user to gain quickly confidence that the core boundary-scan to boundary-scan pin connections of a design are defect-free.

And - ProVision Designer Station also includes a unique scripting library.