In Formula 1, there’s nothing that is not constantly scrutinised in order to glean more improvements. Yet only the driver and the car manufacturer who have mastered the overall package can reap the world championship crown. Despite all the optimisations and specifications, cutting tools for turning have by no means reached the end of their potential for improvement. Responsible tool manufacturers not only think about selling as many cutting tools as possible but also include the tool holders and cooling supply into the equation. On the other hand, users should be open to tips and not only let consulting manufacturers approach them, but also allow them into the production process. The potential that can be achieved in this way can provide a decisive leading edge.

Be open to third-party expert tips

For example, Arno Werkzeuge as a manufacturer has long been involved in the continued development of tool holders and coolant supply. Thanks to its customer proximity, the family-run company not only has a wealth of expertise from numerous applications, but also a wide range of holders with and without coolant supply. Users can rely on the best overall packages for small and large batches and for Swiss and fixed headstock lathes. "Here, too, we are not interested in maximising sales figures for high-margin products. Our aim is to find the best solution for our customers," assures Sales Manager Dieter Wollensack from Arno Werkzeuge. As an experienced technical advisor, he focusses on long-term and intensive customer relationships. He hates it when some colleagues promise "double the service at half the price" and pie in the sky. "I sometimes say to my customers "No, that's not possible" or "We won't do that" and risk being turned down. I've always been successful with this approach - and ultimately so have my customers."

Advice or not, products for process optimisation have to be convincing in practice. For this reason, the overall package consisting of cutting insert or indexable insert with a matching tool holder and high-performance cooling must always deliver the best performance for customers. And this is exactly what users should attach importance to: that their tool partners understand the processes and have the right overall package for every production situation. For example, universal packages for small batches or high-tech solutions for large batches as well as special products for difficult-to-machine materials. Exorbitant promises never help.

Innovative when it comes to "cost per part"

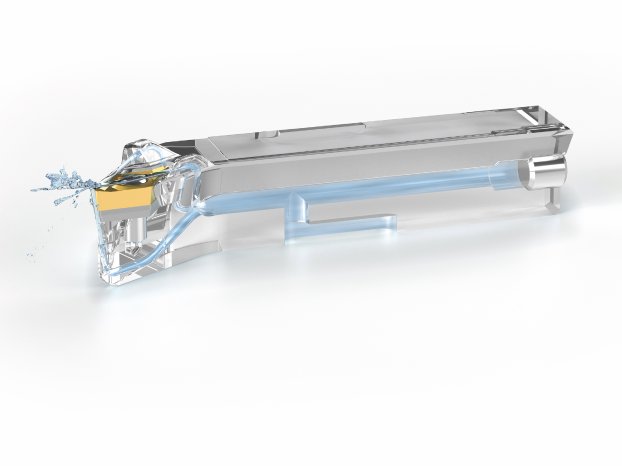

New products and solutions are the end result when tool manufacturers have this type of mindset. One example of this is the clamping holders with through-tool cooling for inserts that Arno Werkzeuge developed in 2022. They are produced using a hybrid manufacturing process and combine additive technology with conventional CNC milling. The result is a tool holder that achieves better surface quality. But why? Because coolant flows directly where it’s needed. Three precisely aligned channels guide the coolant exactly to the cutting edge from above and from underneath without obstructing chip evacuation. The special geometry of the cooling channel creates a nozzle effect that has a greatly improved cooling compared to conventional channels. The outlet openings are always perfect - they need no adjustment. And since they are much closer to the cutting zone, the coolant significantly reduces the temperature.

Experienced users will recognise the benefits immediately: greater process reliability, less vibration, better surface quality and a much longer tool life. Users have sent reports about tool life that is three times longer. Of course, this is not at all suitable for small batches - but when it comes to large batch orders, it’s just the right ace in the calculation where everything has to do with the cost per part.

Hybrid holder: productive from additive

The secret has nothing to do with rocket science - but you have to figure it out first. The shanks of the hybrid holders from Arno Werkzeuge are produced using conventional CNC milling. On the other hand, the complex head part of the holder is attached directly to the shank using a 3D printing process. "This gives us a totally new design freedom and outstanding stability," says Werner Meditz, Head of Technology at Arno Werkzeuge.

The geometric design of the cooling ducts can be precisely optimised so that coolant is guided through the holder to the cutting tool at maximum efficiency and reaches the cutting edge directly from above and from underneath. This cools the tool flanks in a way that was previously unthinkable. At the same time, the number of attachments required at the top of the head is reduced to the absolute minimum. The chip breaks as needed and is optimally evacuated - regardless of the cutting depth. "We get a lot more coolant to where it needs to go," Meditz assures us. The innovative hybrid holder is exactly what clever users want - and this all comes from a tool partner thinking out of the box.

Not only high-tech but also 'basic work'

But even when it's not about high-end, machining companies are happy to have innovative turning tool manufacturers with well thought-out products. How refreshing it is to meet someone who can also offer the right holders and complete systems for small batches with frequent workpiece changes. At Arno Werkzeuge, for example, you will find a wide range of turning holders for external machining, where the length is easily adjustable using a scale. "The Arno Special design is extremely simple and practical when it comes to adjusting the length and coolant access," confirms Meditz.

The holder and through-tool cooling are easy to install and ensure repeatable process reliability. The fact that they are nickel-plated, high tensile and precisely finished promises top quality and a long tool life. The efficient cooling system, which also feeds coolant directly to the cutting edge through three channels, not only ensures long tool life, but also allows higher cutting speeds with optimised chip control. And the machining time this saves makes the cost calculation look good as well.

Variety of boring bars for internal machining

Finally, we come to internal machining. Don't worry, turning tool manufacturers have already given this a lot of thought. First and foremost, the designers at Arno Werkzeuge have also considered the customer’s situations and developed suitable boring bars for a wide range of applications. The range includes boring bars made of steel and solid carbide, each with two possible coolant hole exits. Depending on the turning process, users can choose between a coolant channel from above (IKO) for through holes and a coolant channel from underneath (IKU) for blind holes. Accordingly, chips are guided forwards away from the cutting edge (IKO) or behind the cutting edge and flushed out (IKU). This reduces wear.

Boring bars come in right-hand or left-hand versions with different shank diameters and a wide variety of clamping holders and many approach angles. This variety alone shows that the manufacturer thinks from a user’s point of view. Combined with suitable mini indexable inserts from Arno Werkzeuge, components from Dmin 4.8 mm can be machined effortlessly, regardless of diameter and material. And here, we’re only talking about the standard range, not customised products. The fact that this already promises long tool life because all Arno boring bars are nickel-plated, high tensile and precisely machined, is certainly a boost to confidence building.

Conclusion: tool manufacturers should think with the customer in mind

Users who are looking for suitable, long-life and productivity-enhancing tools for all their turning operations and processes can be glad that some manufacturers actually adapt their thinking to include their customers' situations. If they then accept to start competent consulting and long-lasting partnerships, there is really no way past Arno Werkzeuge.