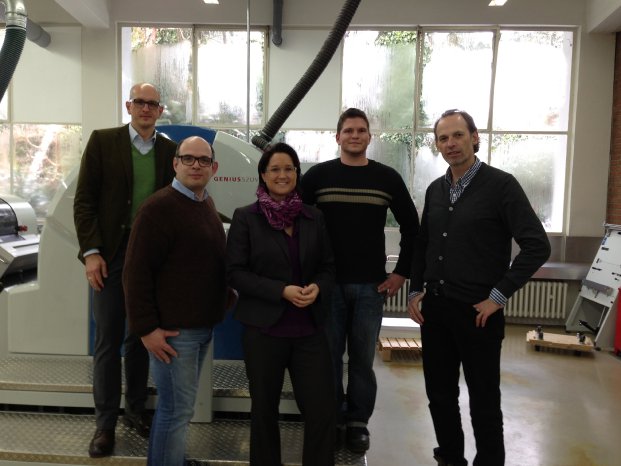

"Finding a profitable niche, where sustainable growth can be realised in a constantly shrinking market, has become a key survival factor for the remaining players. According to the latest edition of Manager Magazine (01/2013), the haulage sector ranks at the top of industries in which companies are endangered by insolvency, closely followed by the printing sector. That is a challenging trend to say the least, and has forced print businesses to rethink their positions. This rethinking process has led us to the innovative KBA-MePrint technology offering. The waterless sheet-fed offset printing press Genius 52UV has allowed us to add new products to our portfolio, which will impact the future development and restructuring of our company positively and sustainably. The creative possibilities now seems endless", reports Jakob Stiels, Managing Director of Stiels-Werbedruck GmbH & Co. KG.

Stiels-Werbedruck GmbH & Co. KG had to date been unable to print on the vast spectrum of non-absorbent materials, like PVC, PC, PS, ABS, PET with their traditional wet offset processes. Due to increasing changes in product structures, however, printing on plastic materials has become ever more important. The company with its 49 employees can now look forward to new challenges in this growth market, for which they are supremely prepared with their new waterless printing processes - specifically in combination with numerous new finishing options based on the integrated UV coating functionality. In addition to the superior quality of the printed materials, the short setup times and low start-up waste cinched the deal for the company headquartered on the banks of the Lower Rhine River.

"Our partnership with s!ncNOVATION GmbH has led to our focus on the production of items for customer loyalty systems for large commercial enterprises in Germany and all of Europe. That includes primarily the production of gift cards and their associated packaging, as well as POS products. Genius 52UV has opened a new door for our business in terms of technology, and we are keen to include 3D lenticular printing in our portfolio right from the start. Our customers have already been using this innovative technology, which we have had to outsource to date. In conjunction with the Genius 52UV, our in-house agency can now offer clients a lot more creative freedom, and we can already feel a significant advantage in terms of our market position", comments Jakob Stiels with much satisfaction.

The high requirements in terms of creativity for the various print products at Stiels keep the print runs at low numbers, while layout changes are extraordinarily high. Quick job changes and very low wastage rates are of supreme importance for any company wishing to advertise 'low-price products'. With the highly economical and eco-friendly Genius 52UV that has become a non-issue. The ability to post-process the printed materials immediately is another key concern for this innovative company. Oftentimes, the business has just one week from the time of order until the client expects delivery, and this issue was another factor for the company's decision in favour of purchasing a Genius 52UV. The long-standing company, which was founded in 1925, can now look to the future with confidence.

For more information please visit:

www.stiels.de

www.kba-meprint.com