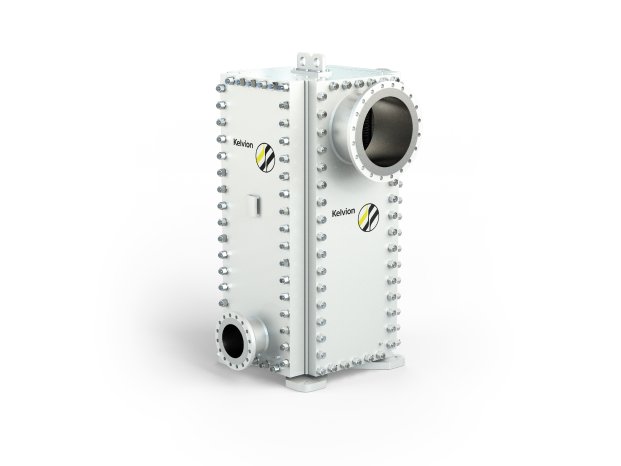

As a high efficient heat transfer solution, K°Bloc is a perfect fit to maximize the efficiency, reduce emissions and the impact on project CAPEX. This expansion will also enable the refinery to produce high-quality fuels of Euro V standard. “We are very happy to help this renowned refinery group to achieve their aim of increasing production capacity with maximized efficiency and minor impact to the environment.” Tanguy Boisselet / Vice-president Sales for Asia-Pacific says.

K°Bloc units were chosen for crude oil preheating duties in the crude distillation unit (CDU) because of its proven experience in providing high efficiency, reliability, robustness and corrosion resistance in the most severe and critical applications They also meet the customer’s specifications for optimal thermal design, energy saving and minimal fouling, compared with conventional shell & tube heat exchangers.

In the CDU K°Bloc units will be used for the following:

- Pre-flash column overhead vapor/crude oil

- Pre-flash column overhead vapor/cooling water

- Light, heavy and full range Naphtha/crude oil

- Kerosene/crude oil

- Kerosene/desalted crude oil

- Atmospheric residue/desalted crude oil