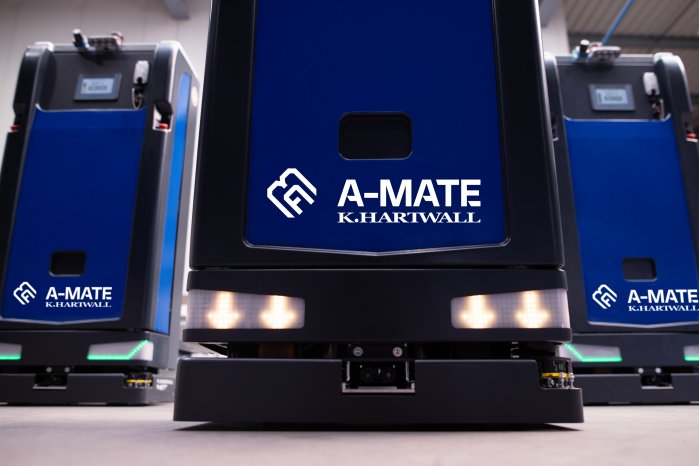

With the A-MATE® Lite AGV (Automated Guided Vehicle), K.Hartwall is expanding its successful

A-MATE® product family. The new counterbalance mobile robot has been designed for transporting dollies, roll containers and pallets in half-Euro size (800 mm x 600 mm) and is equipped with a flexible fork concept so that customised load carriers can also be moved with ease. The maximum load capacity is 600 kg and the maximum lifting height is 300 mm. With the electric free lift, the A-MATE® Lite realises both floor-to-floor handling and special pick & drop actions in and out of, for example, guide rails for dollies. The slim and innovative design in combination with the omnidirectional driving system ensures that the AGV can move easily in all directions, even in confined spaces.

Interoperability through open software architecture

The A-MATE® Lite combines the entire K.Hartwall product portfolio. It forms the link between the transport of large load carriers with the existing A-MATE® FreeLift and A-MATE® Counter AGVs and the transport of small load carriers via the successful co-operation with the ACTIVE Shuttle from Bosch Rexroth. Visitors will be able to see this for themselves, as K.Hartwall will not only be presenting its latest AGV in Hall 8, but also the A-MATE® FreeLift and the ACTIVE Shuttle. The former ensures the automated transport of pallets, large load carriers and sequence racks, among other things, while the ACTIVE Shuttle covers the dolly transport. At LogiMAT, both vehicles will be controlled with ROKIT ‘Onboard Software’ and orchestrated by the ACTIVE Fleet Manager, which demonstrates the interoperability between the various end devices. The A-MATE® FreeLift has significant new features. These include, for example, the new A-MATE View, 3D pallet detection and an RFID device for authenticating different users on the vehicle.

Forklift-free intralogistics

In addition to its mobile robots, the Finnish family-owned company will also be showcasing its successful tugger trains at its stand in hall 8. With the LiftLiner® and LiftLiner® RC, forklift-free intralogistics can be realised. The tugger trains have an extremely small and precise turning circle and transport a wide variety of load carriers - from Euro and half-Euro-sized load carriers to roll containers and dollies. This allows users to avoid the complex pre-sequencing of deliveries, improve order picking and benefit from maximum flexibility during transport. Additional benefits of the LiftLiner® and LiftLiner® RC tugger trains are:

- Loading and unloading from either side

- Compact train lengths

- Fully electric lifting and tilting

- Excellent tracking

Visitors can test the loading and unloading and the selection of returnable load carriers directly at the trade fair. K.Hartwall will also be presenting a lean milk run with various dollies. The modular setup is ideal for logistics processes where the sequence cannot be controlled, and a wide variety of dollies and Material Handling Equipment needs to be combined.

Visit K.Hartwall from 11-13 March 2025 at LogiMAT in Stuttgart in Hall 8 at booth 8B65!