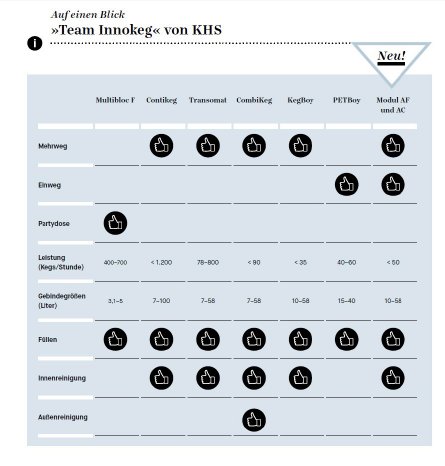

With its new keg modules KHS is offering the craft brewing scene a future-proof system. “When you grow, you can grow with KHS,” says Roger Daum, product manager at the KHS Keg Product Center. The KHS Innokeg AF module enables up to 50 kegs per hour to be processed. Should a positive company development call for filling capacities to be increased, breweries can easily boost their racking output using the modular system. “In this way craft brewers obtain maximum flexibility because they can specifically plan and configure the size of their system depending on the performance and range of equipment they require. The modular approach also keeps the initial level of investment low,” states Daum.

Both returnable and non-returnable kegs can be racked on the Innokeg AF module. The filling system for returnable kegs can be combined with the washing module. With this KHS ensures a high standard of hygiene which meets craft brewers’ quality requirements. The racking module for one-way kegs can either be handled manually or, if required, processed automatically by robots.

The entire system grows with the client

Interfaces for expansions in conveying and keg handling also exist, enabling the entire system to grow as demand increases. KHS also fits its Innokeg AF module with the proven Direct Flow Control system. With this breweries can rack their kegs directly without having to use an indirect return gas control setup. This reduces the amount of gas used on site by up to 40%.

Combined with the Innopro BoxFlash flash pasteurizer, also dimensioned to fit into a single container, KHS now provides a full keg racking, plug-and-produce system which fits into the smallest possible space. KHS has specially designed the Innopro BoxFlash for combined use with the Innokeg CombiKeg filler – right down to the preparation of media such as CO2 or compressed air which is managed jointly for both system components on the flash pasteurizer module.

From the end of 2016 this system can also be fitted with the optional OnBoard CIP module. Thanks to this combination, after production both the Innopro BoxFlash and Innokeg CombiKeg filler can be internally cleaned without the need for an additional external CIP system. Two container parking stations and CIP media dosing pumps have been integrated into the flash pasteurizer for the supply of CIP media. These optimized processes and the compact design cut CIP times for the flash pasteurizer and filler down to a minimum.

More offers for big breweries

Once craft brewers have reached a certain filling volume, it is worth them switching over to a larger system which makes use of tried-and-tested KHS technology. The very successful Innokeg CombiKeg, a container-sized turnkey system with exterior and interior washing, a filling station and integrated weigher, is one such alternative. Up to 90 containers per hour can be processed fully automatically in the smallest of spaces.

For established breweries KHS continues to offer its high-performance Innokeg Contikeg system which racks up to 1,500 kegs per hour fully automatically. For the medium capacity range of between 55 and 800 kegs an hour there is the Innokeg Transomat which was relaunched with an integrated tank system in the spring of 2016.

KHS GmbH will be presenting its extended product portfolio for keg filling this week at Booth 5-147 in Hall 5 at BrauBeviale in Nuremberg, Germany.