The KHS Group has been a symbol of innovative and reliable filling technology for 150 years. "Aspects such as sustainability have become increasingly important in the brewing industry in recent years," explains Manfred Härtel, product manager for filling technology at KHS in Bad Kreuznach. With its new models of the high-performance Innofill Glass DPG and DRS fillers, KHS is taking a major step towards resource efficiency for its customers.

Small modifications, big benefits

The KHS engineers followed this motto during the development of the pneumatically controlled DPG glass bottle filler. Thanks to a new evacuation and CO2 purging process, they have been able to reduce the CO2 consumption of the system by up to 50% and at the same time reduce the oxygen pickup in comparison to conventional methods. This reduction lowers the capacity of the vacuum pump so that it consumes significantly less power and water. On customer request KHS can also equip older DPG fillers with the advantages of the Eco process with the help of a conversion kit.

Maintain beer quality, increase effectiveness

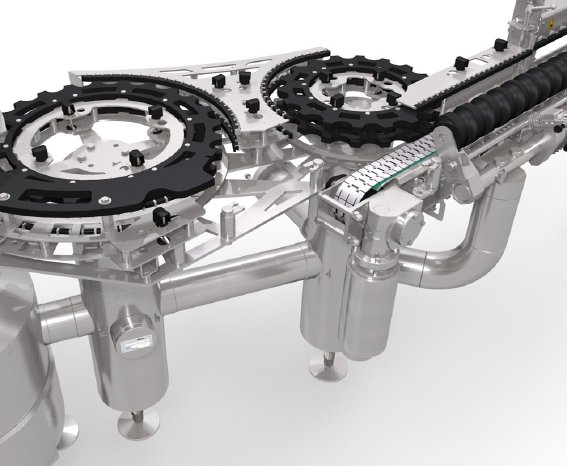

The computer-aided DRS high-performance filler has been a fixed feature in the brewing industry for many years. The hygienic design and fast format part changing ensure high system efficiency and flexibility in production planning. As a new standard, KHS offers the new hygienic QUICKLOCK quick-release locking system for format parts for both the DRS and the DPG fillers. With this system, bottle guide parts can be changed quickly and easily without tools. Thanks to the positive fit, the format parts are held securely in place between the mount and the format part. The time required for filler changeover is thus reduced by about 30% thereby improving machine availability.

Another new feature of the DRS is the optional and patented DIAS diagnostic and assistance system that enables breweries to monitor and optimally adjust the filling process down to the last detail. Pressure sensors in each individual filling valve seamlessly monitor the pressure curve, switching times and step sequences. The system detects well in advance deviations from setpoint values caused by increasing wear. "It also saves time-consuming troubleshooting and avoids the related loss of production time," explains Härtel. This not only results in selective and quick repairs but also supports preventive maintenance measures. The additional option of additionally retrieving filling sequences via KHS' REDIS remote diagnosis system creates the prerequisites for precise support by specialist staff. Using the data, it is possible to statistically assess numerous functions and thus eliminate future sources of failure in advance. This ensures consistent quality and longer machine availability.

Individual systems for increased product safety

With its camera-guided OPTICAM control and monitoring system and the SOFTSTOP bottle flowgate, KHS offers two further innovations in the field of filling technology. Both systems are available for the DRS as well as the DPG.

OPTICAM monitors the foam intensity with two cameras before and after placement of the crown caps. It also continuously optimizes the pressure for the foaming jet in order to remove residual oxygen from the bottles. This allows constant control and regulation of the foam crown independent of the machine operator and thereby ensures a consistently low oxygen pickup. Breweries are thus able to counteract extreme beer loss caused by excessive foaming by reducing today's usual practice of precautionary overfilling; insufficiently foamed bottles are detected and rejected. Production is stopped if there is an increased occurrence of foaming faults.

KHS has developed the patent-pending SOFTSTOP system to smoothly and gently interrupt the flow of bottles. This compact and hygienic built-in bottle flowgate is activated when running at fully capacity. A light sensor measures the distances between containers as they are fed to the filler. A controlled braking wedge then gently decelerates the bottle flow as quickly as possible. The bottles still remaining in the filler are filled and foamed at constant high capacity in consistent quality. "The SOFTSTOP system ensures that the quality of the bottling process remains stable and reduces bottle breakage and noise," concludes Härtel.