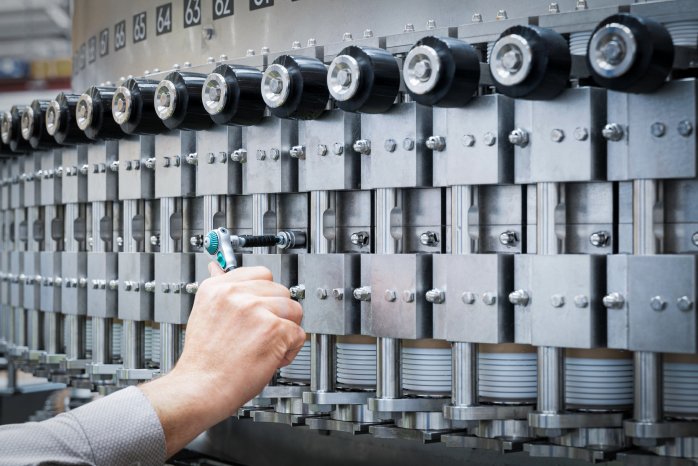

Depending on the container category and machine type, KHS fillers have an average of 125 filling valves. Two employees usually need around five days to overhaul them all. This normally causes long downtimes, during which beverage bottlers are unable to produce. This isn’t the case if operators have a KHS service contract for the rolling maintenance of filling systems, however. Here, just a certain number of valves are gradually replaced and overhauled.

Andreas Krieg, technical support and conversions manager at KHS, explains, “It’s like having your winter tires changed one at a time on four consecutive Fridays, with only ten minutes needed each time. You then don’t have to leave your car at the garage for half a day.” The filling process is only interrupted for a brief period. Around 20 valves can be replaced in the space of two hours. This gives operators greater production reliability and soon pays off, yielding up to eight extra days of production per year.

A service contract for continuous overhauls can be provided on the condition that the customer procures a replacement set of at least 20 valves from KHS.

Mobile workshop on site

KHS offers this service in two process versions. In the classic version customers dismantle the valves themselves and send them to the nearest KHS factory in special transport boxes, where they are overhauled. The parts are subsequently tested and returned. One option is to have KHS service personnel reinstall the valves. This variant has been used by lots of customers, especially in Germany, the United Kingdom and the USA, for many years.

The new and much faster version of the service contract involves the use of a mobile overhaul and test station. This permits all work to be done on the customer site. “To stick with the car analogy, this is like the garage coming to your home, complete with car lift,” smiles Krieg. Customers decide whether they carry out the process themselves or have KHS personnel do so. Says Krieg, “Whatever their decision, our all-inclusive, trouble-free package contains everything you need for one year: measuring devices, an automatic testing facility and all the spare and wear parts needed, including enough sealing rings and easy-to-understand mounting and operating instructions.”

The contract runs for at least two years and can be extended at any time.