JetMaster - an effective, chemical-free, environmentally friendly cleaning process that saves up to 90 % of water consumption compared to high-pressure cleaning, thereby also reducing wastewater volumes accordingly.

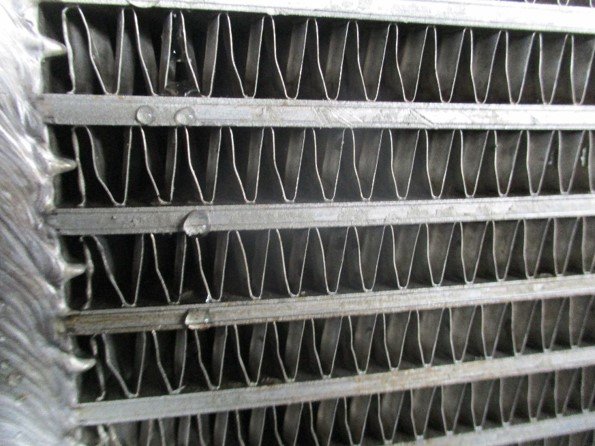

Kipp Umwelttechnik's JetMaster system - manufactured by mycon GmbH, a sister company of Kipp Umwelttechnik - is capable of cleaning even heavily soiled heat exchangers. Even rust can be removed. Thorough cleaning of the heat exchanger structures is the absolute prerequisite for a durable coating.

Basis for the development of a hydrophobic thin coating for heat exchangers:

An important milestone in the development of hydrophobic coating of heat exchangers is the adhesion of the coating to the fins of the heat exchanger. The air flow generated by the fans often also contains dirt particles that act on the coated surfaces. The coating must withstand this - at high temperatures in continuous operation. Proof of the coating's excellent adhesion to the sensitive structures of the heat exchangers was therefore provided as quickly as possible in order to create a solid basis for further development.

The scientific basis of the development through the project partnership with the University of Paderborn:

The adhesion of the coating has now been scientifically tested by the University of Paderborn using the cross-cut method. Using the cross-cut method according to DIN EN ISO 2409, the adhesion of the hydrophobic coating was judged to be excellent (cross-cut characteristic value of 0).

A goal that is worth the effort:

The selected coating material forms a ceramic, extremely solid, smooth hydrophobic coating. As a result, a self-cleaning effect of the surfaces can be expected and the correspondingly extended cleaning intervals result in lower cleaning costs. In addition, the constant self-cleaning of the surfaces can be expected to significantly reduce the energy costs for operating the system.