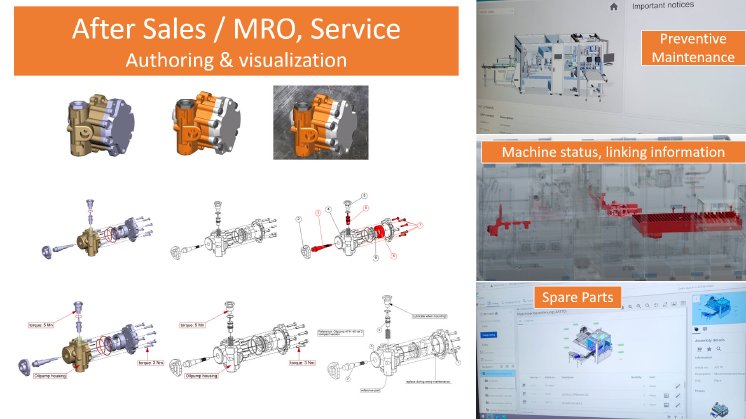

With 3DViewStation, KISTERS provides a tool that can be used for a series of applications in the MRO (Maintenance-Repair-Overhaul) and service sector:

Maintenance and repair instructions require informative graphics. “Creating these with a CAD system is technically possible, but too expensive and too complicated for editors to use. With 3DViewStation, CAD data are loaded from a wide variety of sources, assembly or repair steps are created in a series of views and, depending on the desired result, the assets will be exported as an image or illustration or will just remain as a 3D model.” said Craig Impastato, U.S. Sales Director for KISTERS. The approach chosen depends on the further processing. We still find a lot of 2D instructions today, but 3D is also gaining in importance. “Many customers use the 3DViewStation WebViewer version, for example, to keep 3D content up to date and render it online or offline in 3D mode or in 2D illustration mode. Within the WebViewer, the user can be allowed to rotate a model or visualize it from a different perspective, hide objects, cut them or even measure them.” he added.

Electronic spare parts catalogs are also widely used, in which the 3DViewStation is often used as a 3D graphic component. Here too, the content can be prepared in advance with 3DViewStation. However, in order to reduce costs and be faster on the market, some customers forego this and rely on the intuitive use of the 3DViewStation, e.g. to explode an assembly using a slider and then select components and place them in the shopping cart.

Predictive and preventive maintenance of machines is a frequently discussed MRO topic. According to Impastato, in both cases, the corresponding applications rely on a clear graphic that immediately shows the user where affected components are located within the assembly and can be used to create a link within the 3D scene to related information. “For example, when visualizing a component using 3DViewStation, then a click might link to a repair manual, display historical or real-time operating data, show spare part numbers, supplier data, the date of the next scheduled maintenance, etc.” he explained.

Notifications about problems that are currently occurring on a machine can be made much clearer by adding the powerful 3DViewStation graphics. On the one hand on the machine (HMI) or within an application that accesses the machine in real time. Or within an app that informs a service technician on the move and, thanks to 3D graphics, allows him to recognize where the problem is located and to decide whether it is even worth making a journey without a suitable spare part.

The best possible provision of information, measures and services for a complex product is expected by today's customers in every company. With the KISTERS 3DViewStation, existing 3D CAD data can be reused, processed and visualized in a meaningful way. This leads to a significant advantage over competitors, creates more customer loyalty and helps to sustainably increase sales.

Known for its modern user-interface, high performance viewing, advanced analysis and integration capabilities into leading systems, 3DViewStation ships with current and mature importers for a broad range of 3D and 2D formats including Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, Revit, JT, 3D-PDF, STEP, DWG, DXF, DWF, MS Office and many more.

The latest developments of 3DViewStation can be reviewed in more detail at:

https://www.3dviewstation.com/news/blog.html

KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as Desktop, VR-Edition and HTML5 WebViewer product versions plus the online collaboration tool VisShare. All product offerings are intended to be used together with a PLM, ERP or other management system product configuration, as well as service and spare part applications. KISTERS 3DViewStation provides all necessary APIs. For cloud, portal and web solutions, there is a HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address the needs of complex integration scenarios.