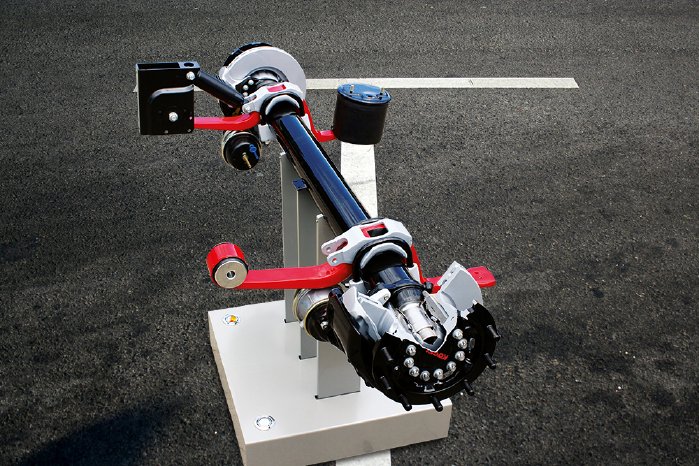

- IAA product innovation

- Exceptionally maintenance-friendly: ingenious connection of the axle tube and trailing arm, tried and tested wheel end and brake

- This unique "double suspension" ensures optimum driving characteristics

The Kögel trailer axle – also known as KTA – features a sophisticated concept: Two U-bolts provide secure clamping of the trailing arm and axle. The axle tube is enclosed by the trailing arm at the top, and the two axle spring seats at the bottom. The shapes of the axle support, the trailing arm and the axle tube have been adapted to the dynamic and static forces encountered in driving and bench tests, in accordance with the latest finite element calculation methods. To facilitate easy repair, the trailing arm and the axle tube can be replaced separately. The axle tubes are forged from a single piece and have no joints. This provides a stress-free transfer of forces and reliable protection against breakages. The trailing arm is made from high-strength spring steel that offers an optimum ratio of spring properties and resistance. A rubber metal bearing absorbs both axial and transverse force at the interface between the bracket and trailing arm. This ensures excellent suspension response behaviour thanks to its optimum torsional rigidity.

This "double suspension", consisting of a soft rubber bearing, and the trailing arm, made from spring steel, is unique in the industry and enhances the driving properties of Kögel trailers. As per the motto: "As much stability as needed, as much damping as possible". In addition, the rubber metal bearing absorbs movement and force from all operating states with no wear, making anti-wear support plates unnecessary. This not only reduces the weight, but also the cost of repair and maintenance-related downtime. The air suspension bellows and the shock absorbers are ideally tailored to the KTA Kögel trailer axle. The system used as wheel end has been put through its paces and has proven itself one-thousand-fold on the marketplace. The result is a reliable and rugged wheel end. The brake is based on a market-proven and recognised braking system that is already in reliable service in thousands of vehicles. Changing the brake linings is child's play, without the need for special tools. The brake discs are easy to change by simply releasing the screws – the bearing settings are not lost. This is made possible by a closed compact bearing. The friction interface between the brake disc and the brake linings is perfectly matched and therefore guarantees the maximum possible service life and braking performance.

The result: The Kögel axle is a maintenance-friendly, directionally stable and reliable axle assembly. It protects the entire semi-trailer combination and meets the stringent requirements of fleets and freight forwarders in the total cost of ownership aspect. The Kögel axle also helps to reduce life cycle costs.

Europe-wide service and parts for the new KTA axle

All spare parts for the KTA will be available via Kögel Parts, the online parts catalogue, starting from the IAA Commercial Vehicles exhibition. In addition to convenient online ordering, a large number of Europe-wide service partners and service workshops are equipped with the most popular and essential spare parts, such as brake discs, brake callipers and brake linings. If it should come to it, this significantly shortens downtimes so that the trailer is quickly back on the road again.

"At the last IAA exhibition, we listened carefully to our customers. That is why we have employed the expertise of reputable suppliers in our new and revised KTA Kögel trailer axle, in addition to our own knowledge", says Thomas Eschey, Managing Director of Production and Technology at Kögel. "With the KTA, we now have an axle unit on the market that is ready for series production, and fulfils our customers' requirements for a low-maintenance and reliable product as well."