The delivery of the high capacity machine reflects the commitment W+D North America has for its customers, according to Kerry Helling, Senior Account Manager, Product Support.

"We're committed to creating the right solution for each customer," said Helling. "So very early in our discussions with Johnson/Anderson we focused on solutions to expand their envelope business, we realized that a re-manufactured machine that met or exceeded original design and performance specifications at a fraction of new machine costs would be the perfect solution."

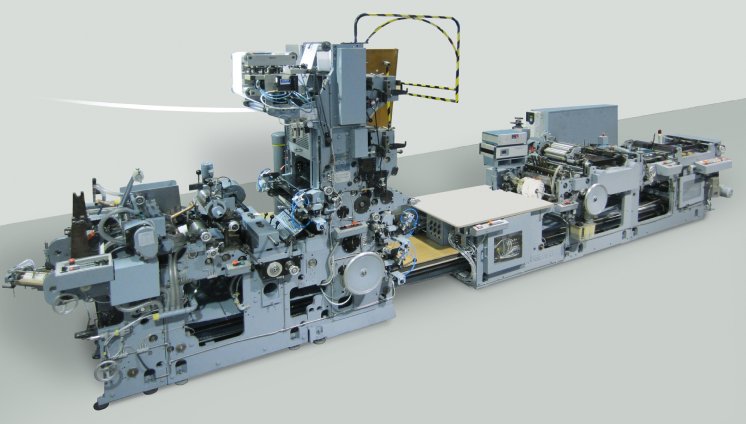

The machine - a 527GSV originally designed and built by W+D - was re-manufactured from the ground up by qualified W+D technicians utilizing original equipment manufacturer (OEM) parts. After assembly, but before delivery, W+D technicians conducted a series of performance tests on the re-manufactured machine and found that it matched or exceeded the performance specifications of the original 527GSV machine.

Jon Laurent, Vice President of Operations for Johnson/Anderson said the performance characteristics of the 527GSV sharpen the company's competitive advantages. "Now Johnson/Anderson can compete in market segments where we have not previously been able to," Laurent said. "With this machine, we gain increased production throughput with no drop-off in quality standards. And the time for our operators to learn how to run the machine is literally a fraction of the time we would have had to absorb with another approach."

Laurent said W+D North America continues being a great partner for Johnson/Anderson. "There are no surprises with them," and "If something comes up, they take care of it immediately."

With the re-conditioning and upgrades Johnson/Anderson selected, W+D expects a 30% productivity gain over typical 527 machines in the market today.

New technology, enhancements and upgrades boost productivity and quality

To increase productivity, W+D added new short change-over technology, including quick change parts for cutting bridges, a magnetic panel cutting section for use with flexible cutting dies and a quick change patch cylinder.

Throughput was increased by upgrading to a belt drive system for the web tower and aligner sections.

Servo main drive upgrades will reduce maintenance and lower energy consumption while increasing overall reliability.

In keeping with Johnson/Anderson's commitment to environmentally sound practices, the company requested modifications to side flaps in the aligner that will reduce paper waste.

The inclusion of a solid state electronic jam detection system increases reliability and overall print quality is bolstered by the addition of doctor blade printing decks.

W+D North America Inc.

W+D North America Inc. is the North American sales and service office for Winkler+Dünnebier envelope manufacturing equipment which includes W+D Direct Marketing Solutions inserting technology and W+D-Langhammer automation technology for the paper, tissue, food and beverage market sectors. W+D North America, a wholly owned subsidiary of Winkler+Dünnebier since 1973, is located in Overland Park, Kansas, USA.