- Eco-friendly development by Pierburg in Neuss

- Suitable for modern engines

- Total orders of over 1 billion EUR

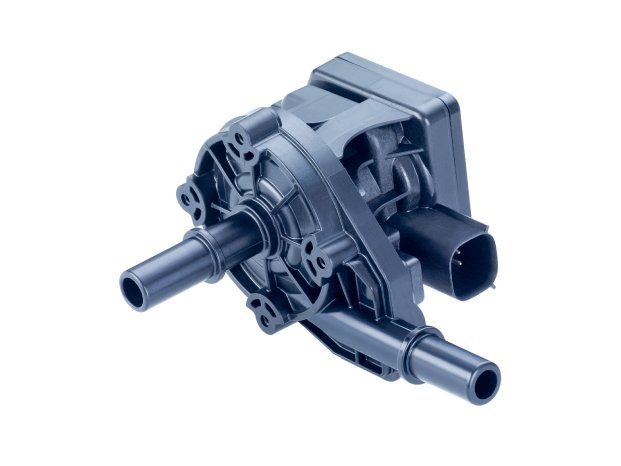

Developed by Pierburg GmbH of Neuss, Germany, the components scrub the activated carbon casing when negative pressure is lacking in the intake cycle, making it particularly suitable for modern engines in hybrid vehicles or direct injectors. At its EVAP production sites in Fountain Inn, South Carolina and in the Shanghai region in China, Pierburg is currently carrying out the biggest project in the history of the company.

Strict regulations govern not only the emissions produced by internal combustion engines, but also those caused by their fuel supplies. In order to meet these standards, activated carbon cases are used to collect the fuel fumes when the motor comes to a standstill or during electric operation, binding these until they can be combusted in the engine. However, because the capacity of the container for storing hydrocarbon compounds is limited, the EVAP regularly scrubs this zone with fresh air.

These new pumps operate with high throughput and simultaneously low pressure, while innovative cooling of the electronics produces strong thermal resistance. This assures that the pumps operate reliably even under adverse conditions in the engine compartment. In addition, they are equipped with an integrated pressure sensor that reports the system pressure to the vehicle’s control unit.