It is the function of the rocker arm to open the intake and exhaust valves of the engine; it is mounted with a plain bearing on the rocker arm shaft.

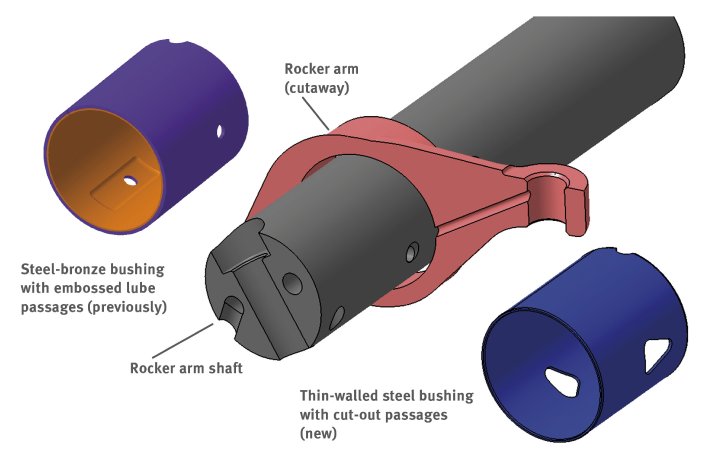

Presently such bearings are primarily steel-bronze composites with a wall thickness of 2 to 2.5 mm. For the purpose of lube oil supply, their surfaces have pockets. These oil pockets leads the required oil flow from the bore of the rocker arm shaft through the bushing into the rocker arm to feed the roller at the end of the rocker arm with oil.

KS Gleitlager produces rocker arm bushings in large volumes. The most recent developments is wrapped steel bushing with about 1 mm wallthicknes.

After the wrapping the bush is nitrocarburated. Cut-out passages in the wall of the bush take over the function of the embossed pockets and route the lube oil into the rocker arm. The reduced wall thickness compared with conventional steel-bronze bushings, has the advantage of less weight, on the one hand, and on the other, there is no longer any need for the interior of the bushing to be machined once it has been pressed into the rocker arm-again a cost advantage. Compared with bronze bushings, the steel variety shows a higher wear resistance and is thus ideally suited for long-life commercial vehicle operations.