Strict legal limits are now in place not only for emissions from vehicle combustion engines themselves but also regarding evaporated emission control. To comply with these limits, an activated carbon canister is used which collects the fuel vapors even when the engine is not running and binds them until they are burnt in the engine. However, since the capacity of the canister to store hydrocarbon compounds is limited, additional fresh air must be injected regularly.

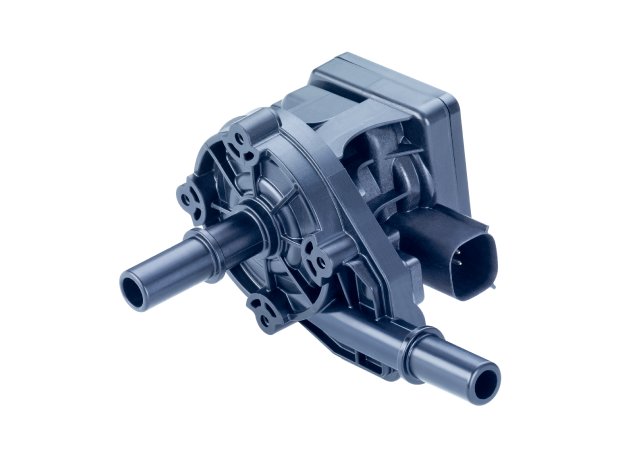

To this end, Pierburg last year launched EVAP, the world's first pump of its kind on the market. The EVAP purges the activated carbon canister without the previously required vacuum in the intake pipe and is therefore particularly suitable for modern engine generations.

It consists of a centrifugal electric gas pump driven by a single-phase motor and operating at high throughput combined with low pressure. Its thermal resistance is enhanced by innovative active cooling of the electronics. This ensures that the pump can withstand the challenging conditions prevailing in the engine compartment. In addition, it is equipped with an integrated pressure sensor to report the system pressure to the vehicle's control unit.

The EVAP is produced for the respective markets in Fountain Inn/South Carolina, part of the automotive supplier's North American manufacturing base, and at Pierburg's Chinese joint venture for pumps (PHP) in the Shanghai region.