Energy savings of more than 50%, cycle times reduced to half and the successful realization of creative ideas in innovative production technologies provide processors with enormous increases in productivity with sustainable and careful use of resources. In hall 13, booth no. B26 the world market leader will present a lot of interesting innovations to the trade fair visitors:

Processing of The New Infinergy® Material on The Kurtz ENERGY FOAMER

Infinergy® by BASF is the first expanded E-TPU worldwide. This new material is elastic like rubber, but light as a feather, and combines the characteristics of TPU material with the advantages of particle foams. These fantastic material properties open up completely new fields of application, but also present totally new challenges in processing. Kurtz exhibits the ENERGY FOAMER shape moulding machine as a customized variation: the Kurtz BOOST FOAMER! This machine technology is already being used with great success in a large-scale customer application. The revolutionary finished products of a global player are being produced on this machine type for the complete world market.

Facade Insulation Panels Produced on a Shape Moulding Machine - THE Alternative Solution with the Kurtz PANEL FOAMER

So far insulation panels for facade insulation have almost exclusively been cut from blocks. The new Kurtz shape moulding machine type PANEL FOAMER provides a real alternative! Insulation panels are now produced on a shape moulding machine saving a lot of production steps necessary with a block mould. Lower personnel requirements, easy automation and the abolition of cutting waste are further positive aspects. Panel thicknesses can of course be adjusted to the requirements.

Kurtz BOX FOAMER - Save 50% Energy and Reduce Cycle Times to Half

The new Kurtz BOX FOAMER provides for a new dimension in EPS box production. Due to its low-mass design, this completely new mould technology achieves cycle times below 28 seconds and energy savings you have ever dreamed about! The processor benefits from a considerably increased productivity also contributing significantly to sustainability. This is a further proof for the "Blue Competence" of a company being a committed partner of the sustainability initiative of the VDMA.

Robot Automation

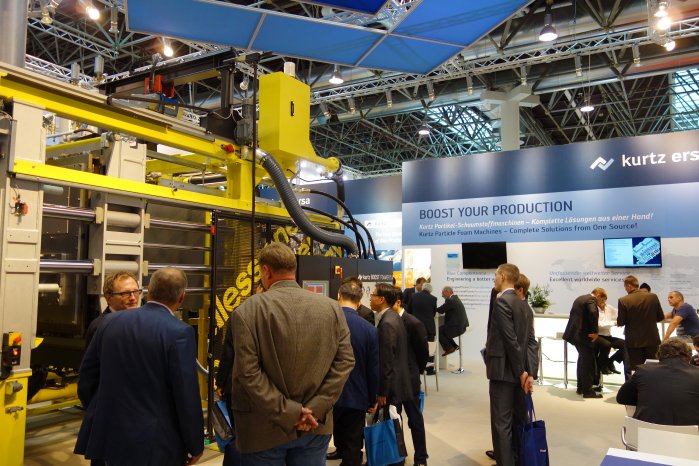

The demand for fully automatic production systems is ever-present - not only in countries with high labour costs. Kurtz has successfully been realizing numerous projects exactly according to their customers' specific requirements! Being the official partner of KUKA, Kurtz has excellent connections and the comprehensive know-how of an automation expert. Visitors of our booth will see a LIVE demonstration of the robot handling system showing part insertion and mouldings removal with additional options.

Complete Solutions for Advanced Processing Plants

Kurtz is your competent partner in the supply of complete plants! Take advantage of our comprehensive know-how all around processing, starting from the selection of the right material to the finished part, no matter whether it concerns shape moulding or block moulding plants. Kurtz has already successfully been installing a large number of complete production plants all over the world, and every year more projects of this kind follow. The decisive factor for a successful project handling is the global organization of the market leader. Kurtz attaches great value to always find the optimal solution for our customers securing and expanding their technology lead on the market. Kurtz provides greatest support already in regard to mould design and mould construction and in selecting the perfect process method - all these are factors having a decisive influence on the economic success of a project. Benefit from the competitive advantages and increased profitable growth!