In the Brazilian municipality Canaã dos Carajas (Federal State of Para) the mining company Vale has opened the world’s largest mining project in history in last December. After starting with the commercial operation in January, LASE has already begun with the rollout of the application LaseBVC (Bulk Volume Conveyor) and delivered 14 volume measurement system for conveyors in the so called S11D Eliezer Batista Complex. Together with our longstanding Brazilian partner company C+ Tecnologia the laser-based bulk material measurement systems will be commissioned for end customer Vale properly. This prestigious project sets a new standard in the mining industry where advanced technology meets high productivity.

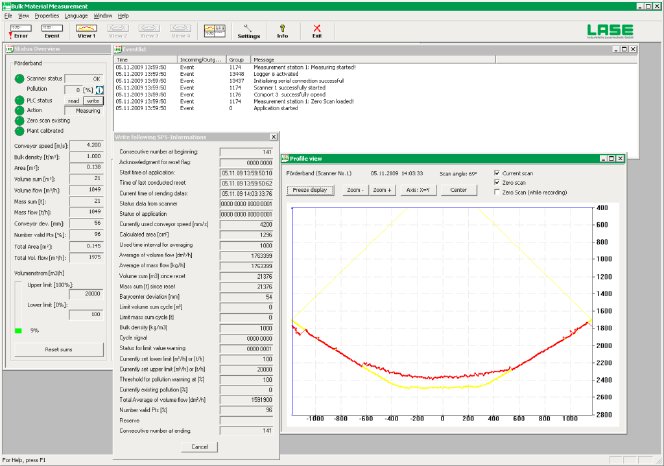

In order to measure the height of iron ore on conveyors as well as its volume, one laser scanner is mounted above each conveyor belt. The scan direction of the laser systems runs across the transfer direction of the conveyed material and generates 2D profiles. These are compared to so called zero-profiles, which have been stored during the initial commission of a conveyor belt. By knowing the individual difference and the belt speed, the exact volume can be determined consequently. Additionally, if the bulk density is known, the mass flow can be calculated, too.

By the use of high-resolution laser scanners with a scan ratio of up to 100 scans per second the material can be recorded even at high transportation speeds. Special algorithms within the LaseBVC software application for the adjustment and calibration ensure high measurement accuracy. The system can be operated intuitively due to an user-oriented dialogue control and configuration wizards for a simple commissioning. For integration in production plants these common interfaces are already integrated: Ethernet TCP/IP, Profibus DP, Analog 0...20 mA and Serial RS 422. Because of its robust design the application LaseBVC allows a reliable operation even at raw environmental conditions.

Find out more on our product website…