“We have been looking for a way to economically decorate somewhat more three-dimensional shapes. With IMD Varioform, we have now filled this gap and rounded off our broad range of decoration technologies,” explains Martin Hahn, in the application division responsible for technology and innovation at Kurz. “The process is highly efficient and offers previously unimaginable flexibility in the selection of surface design, geometry, and molding material. IMD Varioform is the perfect solution to the increasingly stringent requirements of product developers and designers.”

Design changeovers by exchanging rolls

IMD Varioform offers the same design freedom as the IMD process. Design changeovers are performed simply by exchanging the IMD Varioform foil roll. This enables a wide variety of single-image and continuous designs to be processed in the very same mold. It also makes individualized features economically viable. Kurz offers a large spectrum of design and functional foils for its decoration technologies, and these are also available for IMD Varioform.

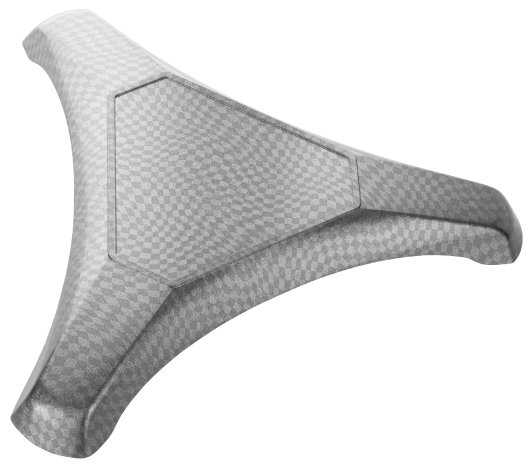

The possibilities include metallized surfaces right through to true-chrome coatings, brushed effects, wood, marble or carbon look, single-image designs plus partial and full-surface backlit designs.

Various tactile properties are also possible, for example smooth surfaces, distinctive structures, or soft touch effects. IMD Varioform foils can also be produced as topcoats formulated to meet customer-specific durability requirements. It is even possible to add touch functionality to the component by integrating the capacitive touch sensors from Kurz subsidiary PolyIC.

IMD Varioform decoration live at Fakuma

The multitude of possible designs and functionality will be on display at the Kurz booth 4122 in hall A4 at Fakuma. Visitors to the Engel booth 5204 in hall A5 will be able to see a live demonstration of the IMD Varioform process on a Duo 1060/350 injection molding machine. The flexibility and precision of the new process will be demonstrated by means of a component with a pronounced three-dimensional geometry.