Flexible and fast integration of functionality

In contrast to In-Mold Labelling (IML), the alternative method used for automated integration of sensors, FFB is implemented outside the injection molding process. The process can, however, follow directly after injection molding. It can be integrated into component production lines, and can operate in inline or offline mode. The touch sensor is permanently bonded to the plastic part in the FFB process. Depending on the geometry and size of the component and sensor, this transfer can occur by means of a vertical or roll-on process.

Specification and process advantages of FFB

The strength of adhesion of sensors applied to the plastic component by FFB was verified in specification testing performed by the automotive sector. While alternating climate tests for the alternative Optically Clear Adhesive (OCA) process found instances of loss of adhesion of the OCA adhesive and a risk of bubble formation, components with sensors integrated by FFB show flawless results in alternating climate tests.

The FFB operation can be performed by the machine operators or can, to a large extent, be automated, thereby providing a never-before-seen ability to cost-effectively integrate sensors in serial production.

Tailored sensor technology

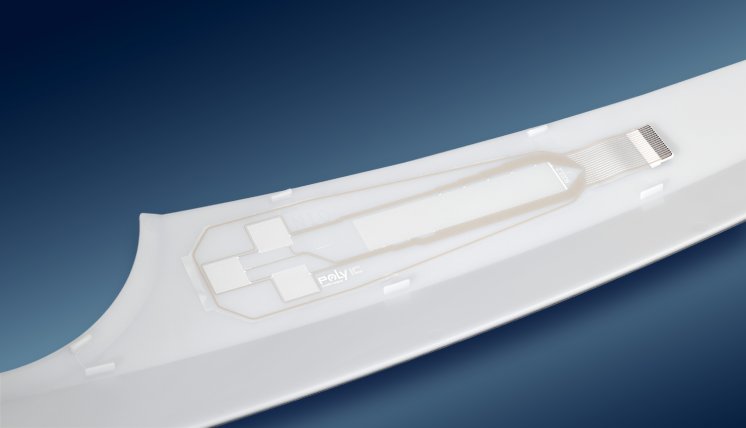

The FFB process uses the highly conductive, transparent PolyTC sensors from the Kurz subsidiary PolyIC. The sensors comprise silver-based metallic grid structures on a PET carrier. They are characterized by their high mechanical flexibility, which enables them to be integrated into curved plastic parts. FFB, just like IML, can also be used to equip arched components with sensors. The flexible PolyTC sensors are ideal for this application. The FFB process places specific requirements on the sensor materials. An important development step was to precisely tailor the PET carrier and the adhesive layer of the sensor to the pressure and temperature process parameters.

FFB enables high-precision positioning

In the case of control panels with visible flexible conductor plates, the controllable area must be located outside the display. Transparent PolyTC sensors, on the other hand, can be placed directly underneath the display panel. This enables all control elements with single- or multi-touch functionality, sliders and wheels, or gesture control to be arranged directly within the display area. Any arbitrary display design can be selected, and the sensor architecture precisely tailored to suit. The prerequisite for interference-free functioning of the sensors is highest possible precision in the relative positioning of the sensors and control panel. While developing the FFB process, particular emphasis was therefore placed on the precise positioning and stable fixation of the sensor on the component. FFB enables the sensor to be transferred precisely, in a repeatable and reliable process.

Component manufacturing live at the Sumitomo (SHI) Demag booth

The door trim that will be equipped with sensor functionality at the Kurz booth has an elaborate day/night design. The design that is visible during daylight takes on a surprisingly different appearance when backlit. The IMD process used to manufacture this sophisticatedly decorated component will be demonstrated live at the Sumitomo (SHI) Demag booth 1105 in hall B1 at Fakuma. The touch functionality of the door trim will be put to the test with the aid of a demonstrator at the Kurz booth 4122 in hall A4. Visitors to the trade fair will be able to activate the day/night design via a touch button, or vary the light color using a slider. They will therefore have the opportunity to experience the complete production cycle from component manufacturing and decoration, sensor integration, right through to the actual touch application.