Foilconnect calculates the required foil quantity and shows the most favorable foil advance mode and optimal axis configuration. After specifying the advance mode, axes and the foil types, the program generates a project sheet that can be used to quickly and reliably set up the stamping machine. Finally, the program outputs the suggested foil ordering details. The project data are saved and can be copied for repeat or similar jobs.

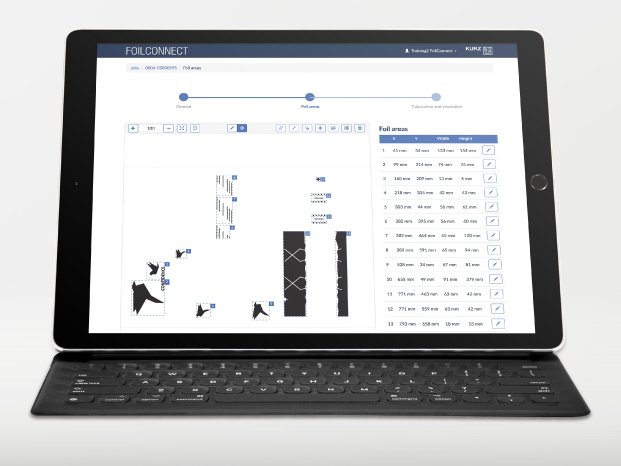

Foilconnect is currently being tested by beta customers. “The feedback we have received has been consistently positive,” reports Roman Strauß, Business Development Manager at Kurz. “We are particularly pleased to see that even well-versed machine operators are using the program enthusiastically because it saves them lots of time. Thanks to the intuitive user interface, Foilconnect is very easy to use. Even employees that have never had to do any foil requirements estimation can work well with it. Foilconnect makes the relevant processes simple, efficient and transparent. The parameters for any stamping job can be retrieved and examined at any time, not only by the person who entered them but also colleagues or the sales department,” explains Strauß.

Visitors to Interpack can test Foilconnect themselves at Kurz booth D25 in Hall 14 and convince themselves of its ease-of-use and high level of functionality.