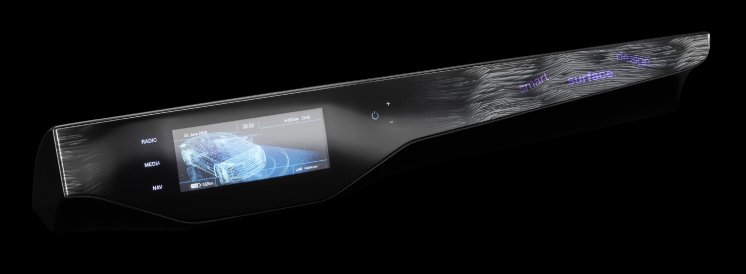

The award-winning automotive HMI instrument panel exhibits a solid, seamless surface. Whereas mostly small design elements are used in the automotive sector, a more striking, larger, nature-oriented design named Fading Lines was developed for this panel. The distinctive design progresses from a gentle gradient to a high-gloss black piano dead front surface. The flowing transitions give the Fading Lines design a dynamic appearance. Besides the unusual surface design, the geometry of the component also exhibits a special characteristic. The display area of the component transitions into the operating panel in an organic curve. This accentuates the operating area, and the curved geometry acts as a tactile aid.

Diverse touch functions under a seamless surface

The central operating element of the instrument panel is a touchscreen with multi-touch function and supplementary touch buttons. In addition to this, the panel contains touch controls for turning on mood-setting ambient lighting. These touch controls are only visible when the panel is backlit; when the illumination is deactivated, the surface appears solid and opaque.

The diverse functions are controlled via several sensors that have been integrated into the instrument panel using a variety of processes.

The detailed surface design of the instrument panel measuring almost one meter in length was created as a single image using the IMD process during injection molding. The sensor for the multi-touch panel was integrated into the rear by IML (In-Mold labeling) during the same injection molding cycle. In addition, the instrument panel was equipped with a proximity sensor below the display that was applied by lamination.

The sensor for the light-regulating touch controls was integrated by FFB (Functional Foil Bonding). The patent-pending FFB process from Kurz enables sensors to be fully mechanically and cost-efficiently integrated into plastic parts.

Design, function and integration from a single source

The individual elements of the overall HMI concept were all developed within the Kurz Group. The design of the Human-Machine Interface was implemented by Kurz Digital Solutions. The component geometry, the user interface, and the partially backlightable IMD coating was designed and produced by the parent company. The sensor technology for the FFB- and IML-capable touch sensors was supplied by the Kurz subsidiary PolyIC. The process technology for FFB integration comes from the stamping machine manufacturer Baier.

“Our award-winning HMI concept combines the forward-looking Fading Lines design with sophisticated functionality. That we were able to develop all components in-house in a collaborative effort is a significant success factor for us and is reflected in the cohesiveness of the surface design,” explains Alisa Schäfer, a designer at Kurz.

The award ceremony for the Red Dot Award for excellent product design will take place in Essen on June 22. The prize-winning HMI display panel concept from Kurz will also be presented in the International Yearbook Product Design 2020/2021, which comes out in July 2020 and will be on sale worldwide.

About the Red Dot Design Award:

In order to appraise the diversity in the field of design in a professional manner, the Red Dot Design Award breaks down into three disciplines: the Red Dot Award: Product Design, Red Dot Award: Brands & Communication Design and Red Dot Award: Design Concept. With more than 18,000 submissions, the Red Dot Award is one of the largest design competitions in the world. In 1955, a jury convened for the first time to assess the best designs of the day. The name and brand of the award were developed in the 1990s by Red Dot CEO, Professor Dr. Peter Zec. Since then, the sought-after Red Dot is the revered international seal of outstanding design quality. The winners are presented in yearbooks, museums and online. For further information, visit www.red-dot.org.