The answer to current trends

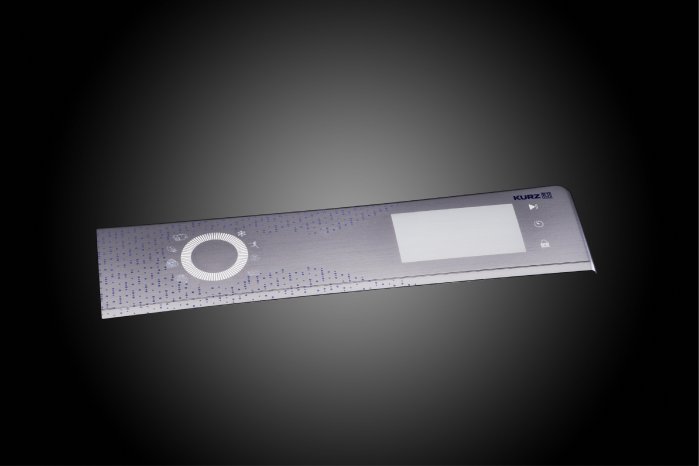

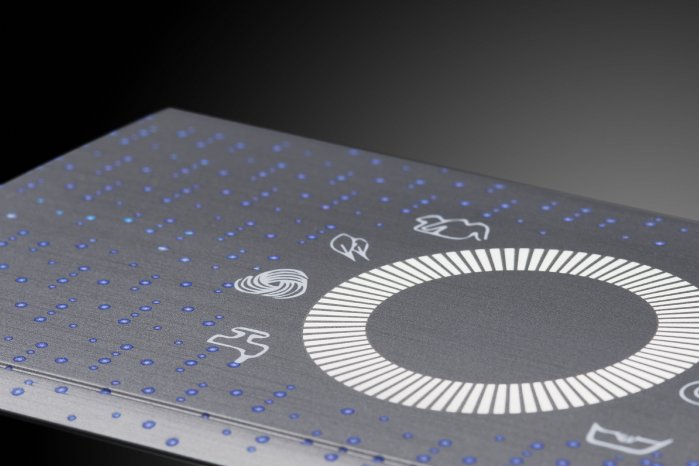

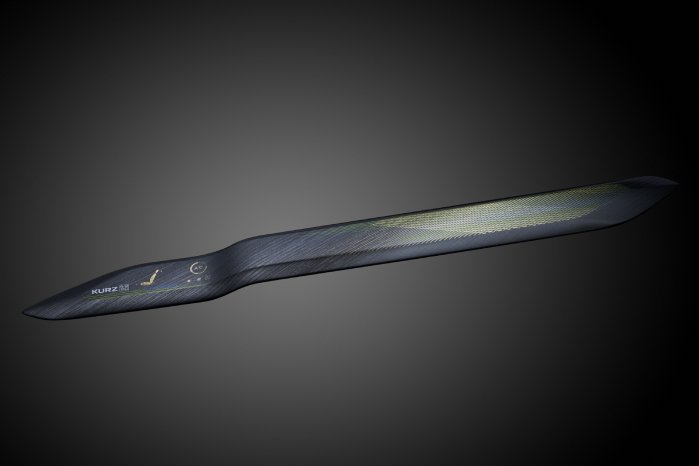

Nikolas Wagner sees great potential for the patent pending IMD UNIFY process, not only in the consumer electronics and household appliances industry. The trend is increasingly towards smart devices with touch operation and state-of-the-art, customized design with seamless surfaces and no mechanical buttons or switches. LEONHARD KURZ can cater to these trends with IMD UNIFY. Particularly in the automotive sector, highly efficient customization of series and unique models is more in demand than ever before under the keywords ‘rapid manufacturing’. The combination with backlighting and Shy Tech effects is just as feasible as the use of touch sensors in different integration variants - for example, through Functional Foil Bonding or functional In-Mold Labeling. In addition to special series and single-image decorations, IMD UNIFY also makes it possible to implement full-surface decorations for the first time. Even 3D deformation of components is generally straightforward. Nick Wagner sums it up: “Everything that is possible with the conventional IMD process can also be implemented with IMD UNIFY!”

Sustainable through efficiency and consistent end performance

At the same time, the innovative finishing option also takes into account the ever-increasing importance of sustainability. On the one hand, In-Mold Decoration is generally more efficient and sustainable than previous processes, as it combines the two production steps of injection molding and decoration in just one processing phase. At the same time, the new surface decoration variant makes an important contribution to the longevity of the products, thanks to the significantly more adhesive and durable overprinting. In addition, the IMD UNIFY premium decoration process has no effect on the recyclability of the components, which can therefore be easily returned to the recycling cycle.

Machine expertise from the KURZ Group

At Fakuma, LEONHARD KURZ will be demonstrating the possibilities of forward-looking surface decoration on a hybrid machine from its subsidiary BAIER, which combines digital printing and hot stamping. The company will demonstrate the subsequent finishing of a 3D-shaped automotive door trim and the customization of a washing machine panel through digital overprinting live at the stand. Ljubisa Drinic, Managing Director of Baier Maschinenfabrik states: “We are delighted to be able to show trade fair visitors how IMD UNIFY enables us to decorate KURZ surfaces in a modern and customized manner according to customer specifications, to get the component to perform in a way that is unprecedented in our core markets to date. Changing decors and components in the machine is very quick and easy, as we will be demonstrating at Fakuma.”

Online presence leading up to Fakuma

LEONHARD KURZ is also using its trade fair presence in Friedrichshafen to kick off a comprehensive online presentation of the company’s innovations and exhibition highlights. Visit www.fakuma.kurz.de for detailed information and extras such as videos or 3D animations on Fakuma products and topics.

At a glance

Fakuma 2021 - October 12-16, 2021

LEONHARD KURZ Stiftung & Co. KG Hall A4, Stand A4-4122

Product group: Machines and equipment for finishing, decorating, printing, and marking

Trade fair presentation focuses on: Automotive interior/exterior, consumer electronics, home appliances, sustainability