Surface design with color-fast light design

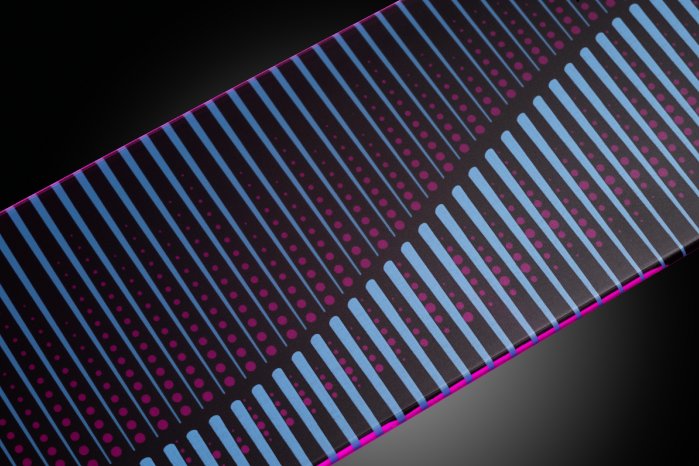

It’s a familiar problem for manufacturers from the automotive sector: If, for example, a black surface is illuminated, an undesired greenish shimmer sometimes occurs - a typical example of the so-called chromaticity displacement phenomenon. But this problem is now a thing of the past! Using various demonstration devices, KURZ will be presenting impressive light designs - developed in cooperation with MENTOR - at Stand A19 in Hall 5. Thanks to a proven RGB algorithm, company-specific corporate identity colors can be implemented with full color fidelity. Light and surface design merge to create an innovative, futuristic design with fantastic effects and a high degree of customization.

Targeted light distribution and dynamic designs

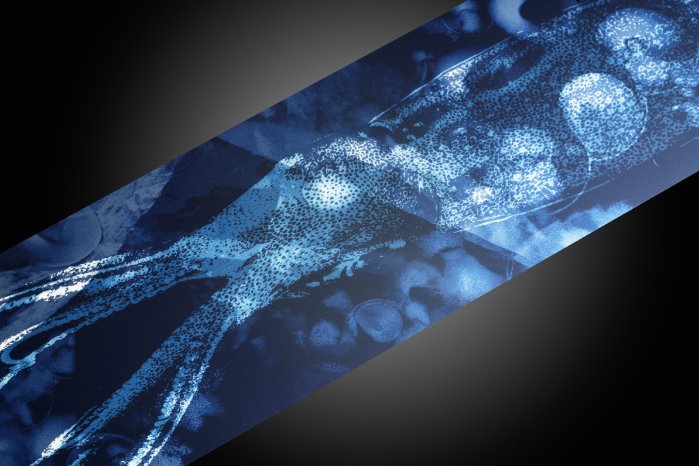

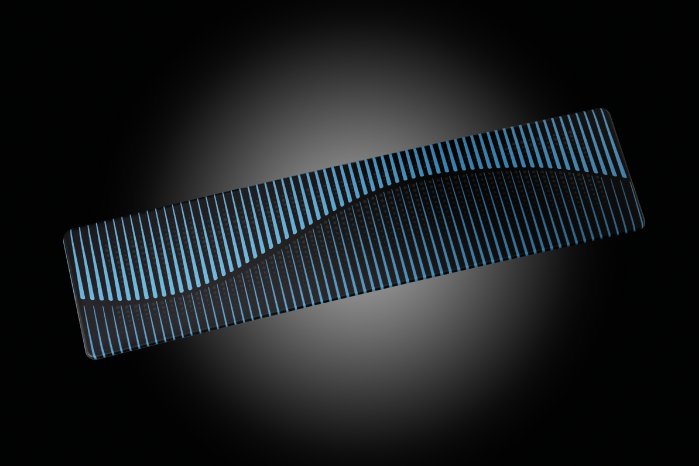

The new process also advances the automotive industry in terms of light distribution. “Unlike conventional processes, the light can be directed, distributed, and, in the right places, decoupled in the desired form, color, and brightness,” explains Rainer Süßmann, Head of Business Area Plastic Decoration and Global Sales Director Automotive at KURZ. “Surface decoration and light effects are optimally coordinated. This means, for example, that gradient effects and motifs with different brightness levels can be implemented - perfect for challenging color light applications.”

Dynamic motifs can also be easily realized with the solution developed by KURZ and MENTOR. “With the help of LEDs, which are controlled independently of each other, individual symbols or entire surfaces can be highlighted dynamically,” explains Dr. Höner, Head of Light and Electronics Development at MENTOR, and continues: “What’s so special about it is that the light channel separation eliminates the otherwise occurring light scattering effect. The light can be controlled in a targeted manner, creating the impression of real movement.”

Redefining industry standards together

Together, KURZ and MENTOR ensure leaner production processes. Thanks to the close partnership between the two experts, new designs can be developed more quickly, on the one hand, and less coordination is required in production, on the other. Customers benefit from a high level of efficiency. Both companies have also focused on sustainability and have in-depth expertise in this area. “Together, we have succeeded in reducing the number of LEDs and the associated power consumption. What’s more, thanks to the optimal interplay of surface decoration and light, less varnish needs to be applied than before,” explains KURZ’s Rainer Süßmann. “In this way, we offer our customers a high level of cost-effectiveness combined with sustainable added value - or in a nutshell: Pre-series electronics according to the latest automotive standard.”

At a glance

K 2022 from October 19-26, 2022

LEONHARD KURZ Stiftung & Co. KG: Hall 5, Stand A19

Product group: Machines and equipment for finishing, decorating, printing, and marking

Focal points of the LEONHARD KURZ trade fair appearance: Automotive interior/exterior, consumer electronics, home appliances, sustainability