- Libiao Robotics introduces a range of upgrades to AirRob automated system

- Enhancements to efficiency, safety, functionality and customer support

Stock-Taking

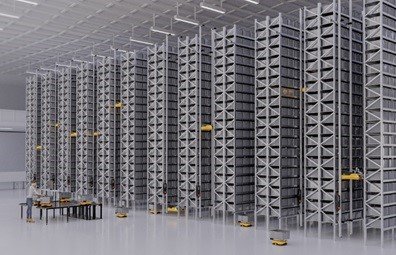

Whilst principally used as a means to boost a warehouse’s storage and picking performance – AirRob has been widely deployed across Europe, the US and Asia by household-name retailers and eCommerce businesses – the system can now additionally be used to double-check stock in a warehouse at those times when it is not required to perform its primary function.

In high-throughput warehouses, where a large number of SKUs are moved in great volumes, the actual stock level doesn’t always tally with the figures shown on the inventory ledger. This can cause problems, particularly if a customer places an order on the understanding that an item is in stock, only to find that it is in fact a stocktaking error. If the purchase is mission-critical, for example a birthday present or equipment needed for an upcoming trip, that customer will feel let down and is unlikely to return with future orders.

Now, with AirRob’s enhanced capabilities, it can be set to work at the end of a shift, when it would otherwise have been decommissioned for the night, and get to work consolidating the remaining stock with the recorded amount. The AirRobs move totes out of the racking and place them on one of the fleet of floorbots, which then take the totes to a RFID scan tunnel to map and record its accurate contents. The system can be set to perform this task autonomously - all that’s required is a remote software update - thus saving considerable labour when ensuring accuracy of stock.

Multi-Function Workstations

The fundamental purpose of the AirRob system is to bring totes to workstations, where workshop operatives take out the goods and make up orders ready for dispatch to the customer. Having have spent time with customers looking for ways to further improve the process, Libiao’s team of warehouse robotics design experts have introduced greater functionality at this point of the warehouse operation. The result is that the workstations have become multi-functional, offering the opportunity to carry out additional activities, including:

Decanting – removing incoming merchandise from its packaging, placing it into a tote, and sending it to storage;

Consolidation – combining more than one SKU into a tote to optimise storage density;

Cycle-count – enabling the warehouse operative to call forward totes to visually check the inventory;

Exceeding – if slow-moving items are taking up tote space, they can be reallocated to be placed on pallets outside of the storage grid.

Furthermore, when required, a workstation can be adapted to handle returns, with the addition of an additional terminal and hand-held scanner. In this scenario, the floorbot returns items back to the racking once it has brought goods to the workstation. This capability can be especially useful during peak periods when higher volumes of inbound returns can threaten to disrupt the outbound flow of orders.

Efficiency Upgrade

With thousands of bots in operation at live customer sites around the world, Libiao technology is enhancing warehouse flows in a wide variety of facilities. It is through the capture and analysis of this data that Libiao’s engineers can apply upgrades to the software and algorithms that control the robotics to improve efficiency even further, without the need for any hardware add-on.

In an industry where time is money and maximum uptime of systems is essential to profitability, the upgrades allow existing AirRob customers to benefit from even greater levels of efficiency and accuracy. The implementation of these upgrades is seamless and can take effect without a second’s break in operations.

Enhanced Safety

In warehouses where fleets of robotic devices operate autonomously, it is rare that a human being is required to share the same piece of floorspace. However, should the likes of a service engineer or racking inspector need to access an area where bots are moving, Libiao has introduced a system that protects personnel from moving devices whilst having minimal detrimental effect on ongoing warehouse operations.

Using a system of gates fitted with safety interlocks, robots operating in an aisle are temporarily disabled when a gate is opened, and will restart when an ‘all clear’ message is detected. Unlike other systems that shut down the whole operation in a particular area, or require expensive detectors fitted to every piece moving equipment, the Libiao solution is cost-effective and easy to fit, and can be assigned to individual aisles without affecting the rest of the operation.

Design Tools

AirRob is widely praised for its swift implementation, as it requires virtually no infrastructural modifications to a warehouse and can operate optimally on standard warehouse racking. Looking closely at the timeline from initial consultation to go-live, Libiao’s engineers identified a way of shortening that even further. With the introduction of AirDesigner, Libiao’s consultants and partners can now design a AirRob system for clients even faster, marking a considerable enhancement to an already fast-turnaround robotic solution.

Not only can warehouse designers now visualise more accurately a proposed installation, but the efficient new AirDesigner tool can also automatically generate an equipment list, removing an often laborious element of the pre-installation process.

Customer Support

Libiao prides itself on the close relationships it builds with it customers, and is prepared to stand by their sides at all times, helping them run their logistics operations as smoothly as possible even during extreme peaks such as Black Friday and Singles Day. It has now drawn on its AI expertise to introduce a new AI ChatBot, an after-sales enhancement that enables customers to gain fast access to knowledge at the touch of a laptop keyboard or smartphone screen.

Operating 24/7/365, Libiao’s AI ChatBot is designed not to replace its existing after-sales department but to supplement it with a means to offer customers a fast and accurate response to simple and frequently asked questions such as system specifications and maintenance matters.

Meet the Team

Libiao Robotics will bring a strong team of engineers and consultants to its LogiMAT stand (1GA37), including a selection of German-speaking personnel from its European headquarters in Frankfurt. It will be demonstrating its AirRob system and hoping to attract the attention of warehouse owners and operators looking to boost the efficiency and accuracy of their operations, as well as reinforcing relationships with its existing customers and partners.

www.libiaorobot.com