With Gocator 200 multi-point scanners, users can create a scanning system based on a modular design that allows a mix of 3D profiling, tracheid detection, and color vision for sawmills and planer mills looking to maximize wood breakdown decisions.

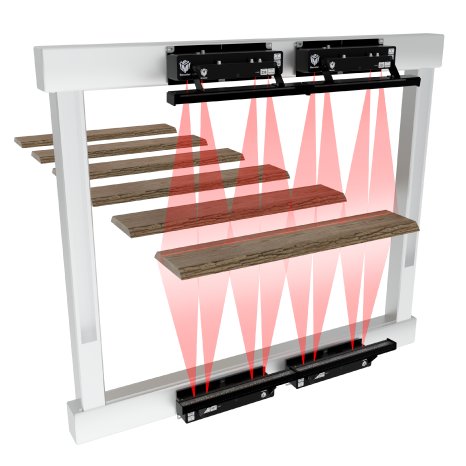

The G200 series is based on coplanar scanning that effectively captures both the leading and trailing edges of lumber while minimizing conveyor footprint, offers true differential profiling for accurate thickness measurement, and can scale from 1 to 48 sensors to cover various lumber length requirements.

Based on the proven high density profile design of chroma+scan, Gocator 200 scanners run 50% faster to achieve scan rates at 3 kHz matching mills running at 300 feet per minute. In addition, tracheid scan rates are 3x faster to deliver 1.5khz density for exceptional detail in wood grain detection.

“Gocator 200 gives customers a modular advantage so that saw and planer mills can now create their own custom material optimization solutions. We are excited by the possibilities the G200 offers to the wood industry including the many benefits of Gocator’s proven all-in-one 3D smart capabilities”, said Terry Arden, CEO of LMI Technologies.

With the launch of the G200 series, LMI is also expanding the capabilities of its standard Gocator Software Development Kit (GoSDK) with a new Web Scanning SDK (GoWebScan). GoWebScan SDK allows users to quickly and easily implement their own solutions by taking care of common tasks like system alignment, and merging data from multiple sensors.