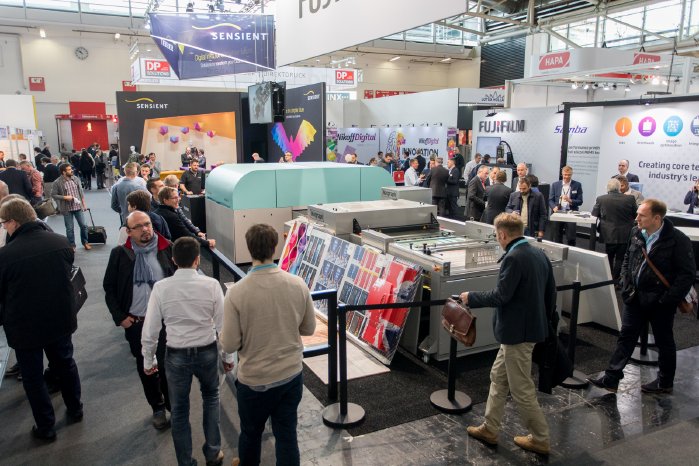

126 print tech companies from 20 countries will showcase real game changers, specifically designed to facilitate complex printing processes by efficiently applying inks, liquids, and 3D material to various shapes and substrates. The new Online Show Preview is an essential resource for navigating InPrint Munich 2019, giving a taste of the wealth of topics, technical innovations and expertise offered at the show.

With inkjet printing on the rise in many industry sectors, printhead technology is one of the main focus areas at InPrint Munich 2019. World-leading manufacturers such as Xaar and FUJIFILM present their broad portfolios of new printhead designs and solutions. Seiko Instruments shows a recirculating print head for aqueous ink, adding special visual and haptic effects. People&Technology focuses on printhead cleaning systems and showcases a new digital system for testing printheads and inks in one go. TOSHIBA TEC has developed a compact printing solution with a 600npi inkjet print head, which can print two different colors at 300npi.

Parallel to printhead technology, the printing inks sector is evolving fast, offering an ever-growing range of new ink solutions for specific applications. Tritron presents its latest high-quality inkjet inks for product decoration, including water-based and UV/UV LED curable inks. Agfa will showcase dedicated industrial inkjet solutions for decoration, serialization, product printing, marking and coding. Marabu offers ink for metal, plastics, textiles, glass, ceramics, wood and other materials, developed in line with customer-specific requirements. AFFORD INKS presents a broad range of inkjet, screen and pad printing inks, including aqueous and latex inkjet inks, textiles inkjet inks, and eco solvent inks.

The fast advance of robotics in industrial manufacturing urges companies to explore the potential of integrating print technology with robotics for faster and better processing. ITW Morlock puts the focus on robot-based inkjet printing with specifically developed software for communication between the industrial print head and the moving robot arm. Global Inkjet Systems (GIS) presents its latest innovations in robotic automation for digital printing systems. Bergstein Digital offers high speed printers to print direct on shaped products in combination with robots and other automations.

Optical systems, though often underestimated, build the core of any successful implementation of print technology in the manufacturing process. Baumer Inspection exhibits a new inspection system for single-pass printing on flooring planks, packaging, textiles and film with variable motifs and batch sizes. DeCoSystem shows an easy-to-integrate quality control solution for waste reduction and printing process optimization. TECHNIGRAF presents their latest UV measuring technology, and KRÜSS has developed an innovative optical system for analyzing ink droplets produced by the print head.

Curing Systems offering fast ink and varnish drying help to boost production times. Phoseon Technology and Armada Trade & Development present new UV-LED curing solutions with low energy consumption for low-noise, consistent and scalable curing. Hamamatsu Photonics Deutschland launches a low-energy electron beam source for curing surfaces and thin films. Dr. Hönle AG, UV Technology shows a new curing system with intensities of more than 18,000 mW/cm² for fast curing.

Smart Software is required to manage and optimise industrial printing workflows and automated manufacturing processes. ColorGATE Digital Output Solutions presents its comprehensive portfolio for standardization and automation of the entire production chain with workflow, RIP and color management solutions for industrial digital printing. CADIS Engineering offers customized software components for manufacturing systems that are adapted to the substrate. Meteor Inkjet launches new software to drive industrial inkjet printheads that dramatically improves the print quality of single-pass systems.

Inkjet-based techniques for 3D printing have become a major focus especially in the automotive, aerospace and electronics industries. TCS Topo Color Systems presents a high-res 3D topological scanner to scan surface structures for haptic décor print. ChemStream translates customized material problems into sustainable chemical formulations for 3D inkjet printing. PROFACTOR presents multi-material and multi-layer 3D printing solutions offering the possibility to integrate additional functionality. relyon plasma showcases a range of tools for plasma activation in 3D printing to improve adhesion.

Information on more exhibitors and their products can be found in the new Online Show Preview which is now available for free download. Published as a bilingual document in both German and English, it features exhibitor profiles and product descriptions, an article by Dr Holger Busch, VDMB, a programme guide of conference sessions and speakers, and some key visitor information.

Conference programme extended

More than 60 international expert speakers are presenting at the technical conference, leading the audience through the necessary steps to successfully implementing new print technology into complex production lines. Latest additions to the programme include:

- Creative with printed electronics: from idea to product (VIGC): Explains the route from concept towards a final printed electronics product (e.g. smartphones) involving digital printing and finishing.

- One-step metallization: high throughput bus bar manufacture for printed electronics by inkjet (M-Solve Ltd): On combining inkjet-printed metal with near-infrared drying and laser sintering to manufacture bus bars for printed electronics.

- 3D-printing from the perspective of a service provider (3D-LABS GmbH): Upcoming trends, possibilities and workflows using polymer technologies, detailing pros and cons.

- Printing 4.0 (Meyerburger): On the benefits of inkjet printing, with specific examples for the manufacturing of solar cells, printed circuit boards and semiconductors.

- Real and virtual plasticity in hybrid scanning and inkjet printing (TCS TopoColor Systems GmbH): Modern hybrid scanning technology to help create 3D haptic structures.

About InPrint Munich

InPrint Munich 2019, the International Exhibition of Print Technology for Industrial Manufacturing, features 126 exhibiting companies from 20 countries, all presenting technical innovations in digital, inkjet, screen and speciality printing on diverse shapes and materials, including flat or curved plastic, wood, foil, textiles, glass, ceramics and metal.

Equipment and services on display are specifically developed to facilitate the cost-efficient conversion and customisation of industrial and consumer goods. This includes automotive parts, printed electronics, packaging, drinking bottles, food containers, fashion items, pharmaceuticals and cosmetics, as well as the decorative finishing of flooring, tiling, interior decorations and furnishings.

The previous event in 2017 attracted some 3,000 high-profile professionals, including inventors, integrators, print service providers and production specialists from a wide range of industry sectors. Alongside the exhibition, the popular Technical Conference with more than 60 international top speakers and a free Consultancy Corner offer additional opportunities for networking and innovation sourcing.

Location, opening times and tickets

InPrint Munich takes place from 12 to 14 November 2019 at the Munich Trade Fair Centre in Germany. Exhibition, conference stages and Consultancy Corner are located in Hall A6, accessible via the East Entrance of Munich Trade Fair Centre. Opening times are from 9am to 5pm on all three exhibition days. Visitors can now register and buy advance tickets online at a special rate. Alternatively, full price tickets can be purchased on-site on all three exhibition days.

Further information on participating exhibitors, conference programme, travel and accommodation, as well as visitor tools, ticket shop and a video “InPrint Munich explained in 60 seconds” is available on the show website.

www.inprintmunich.com

ENDS