By entering the production facilities of Ulster Carpets the visitor will be part of the future in dyeing and finishing. Established in 1938, the family business has long held a reputation for the highest quality and most luxurious carpets in the market place. Whilst quality and tradition haven’t changed since, the technology marks the future of textile finishing: Fully automatic Lab, fabric preparation and dyeing offer unequalled opportunities. Reducing human mistakes to a minimum, results in a superior quality, which still marks the baseline of the entire company until today.

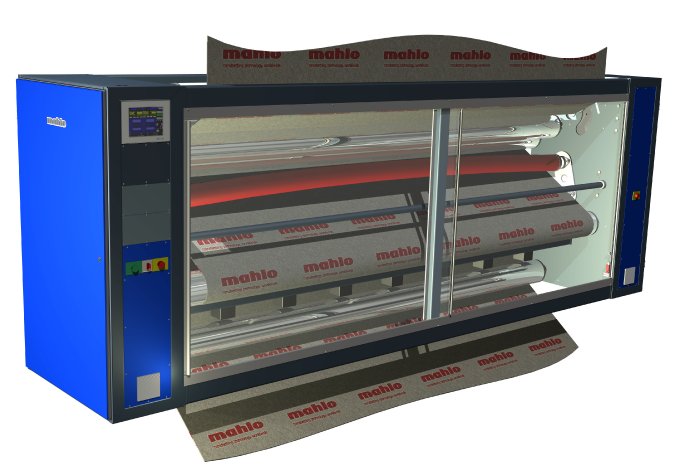

Mahlo is proud to support the high-end setup of Ulster Carpet with the latest generation of automatic weft straighteners. The Orthopac CRVMC Carpet Straightener is the specialist for carpets and technical textiles. It is ideal for high mechanical load coming in wide working widths. The unique positioning drive makes sure that irrespective of the web construction the contact between rollers and web is ensured at any time. During the straightening process the force applied to the fabric will be always distributed over the entire width and not – like with common technologies – centralised. On top of that, all the collected relevant data can be used for internal and external statistics, resulting in a higher transparency and a better total quality control.

The benefit for Ulster Carpets: The high standards in quality that they have established over the complete production process will find its climax at the very last point- the weft straightening. By doing so, the carpets delivered to hotels, cruise ships and living rooms will look exactly as professional as promised by the entire spirit at Ulster Carpets.