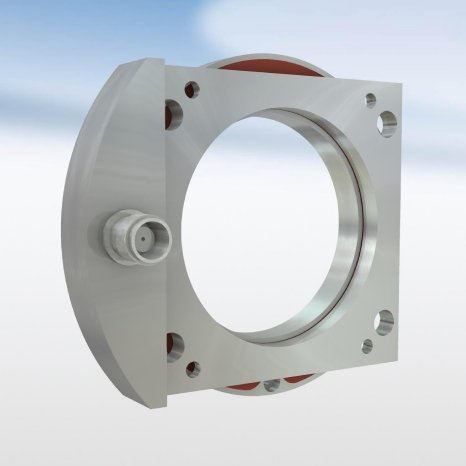

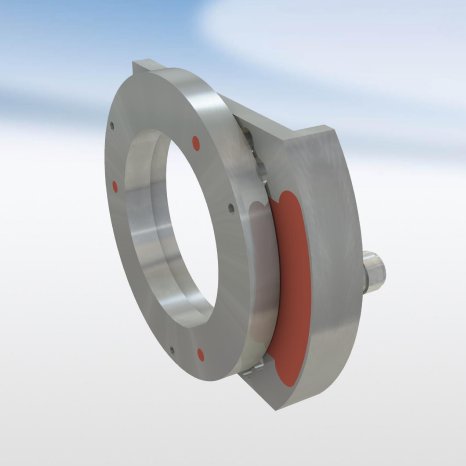

DITTEL’s data storage ring can be mounted onto a grinding or dressing wheel to store data that is relevant to the current process and production conditions. The data is then stored on or can be accessed from the stationary ring with out actually coming into contact with the wheel. It is irrelevant whether the tool is stationary, being accelerated or rotating. The data is protected by different levels of access rights. Parameters such as wheel geometry, tool and machine number are stored on the tool. On reading off the stored parameters, it is then possible to access the relevant workpiece program and automatically carry out the set-up process.

The manufacturer’s security criteria, such as the maximum peripheral speed/rpm or wheel diameter are entered into the controls to reduce the risk of a crash.

Wear criteria such as diameter, number of workpieces, dressing distance and operating lifetime are documented on the tool.

If a dressing wheel has only achieved half it’s total dressing distance before wearing down, the stored data makes it possible to determine what the causes are and take appropriate corrective action.

The data storage and read/write rings are resistant to cooling lubricants and are wear and maintenance free.