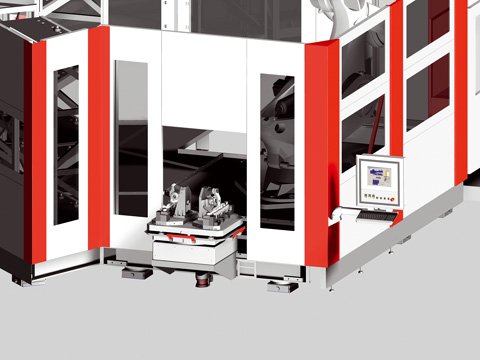

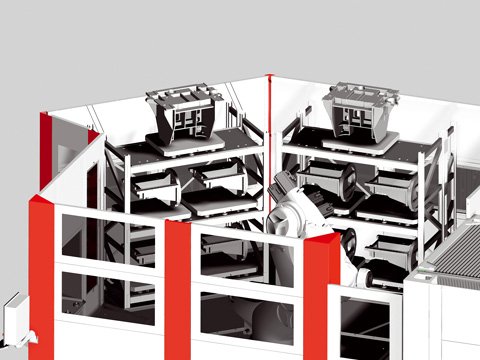

The pallet magazine is designed for pallet dimensions up to L x W x H 1000 x 800 x 800 mm. A sensor-monitored set-up station allows for loading and unloading of the system in parallel to production time and no additional protective enclosure is required. The set-up station can optionally be enabled for rotation and can also be loaded and unloaded with a crane. The attractively shaped and ergonomically designed enclosure with spacious access doors fits seamlessly onto the machining centre(s). The master computer is responsible for control, organisation and monitoring of the entire production system.

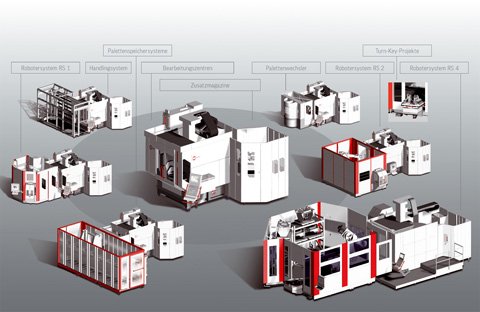

The RS 4 completes Hermle's programme of robot systems extending from the RS1 through RS 2 and RS Kombi, RS 3 to the new RS 4. All machine models of series C 20, C 30,

C 40 and now also C 50 can be completely automated with robot systems.

User benefits at a glance:

- Fully automatic handling of almost any pallet size

- Inexpensive transport and simple installation by means of "hook-ready" designs of the machine and also of the robot cell

- Can be used 7 days a week in multiple shifts

- Integrated software for flexible order management

- Active and passive gripper solutions

- Loading via the set-up station, even during the manufacturing process (parallel to production time)

- Individual pallet storage up to a pallet size of 1000 x 800 mm

- 6-axis industrial robot, transport weight 1000 kg

- High system competence with Hermle as complete system provider