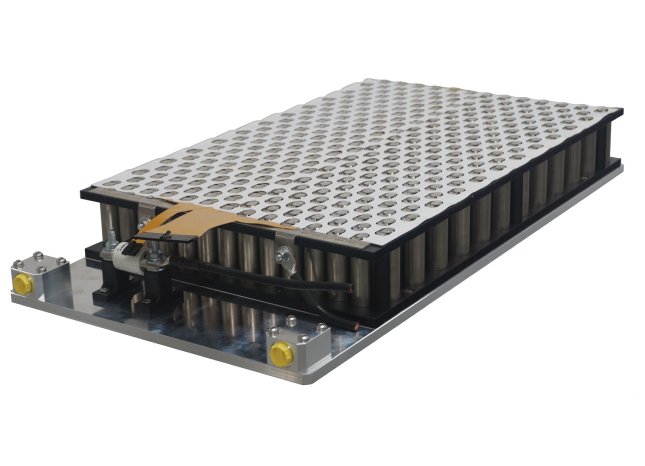

Mersen’s role in this pioneering project is to provide expertise for improving the battery component. With 35 production locations worldwide, the company has invested heavily in research and development in the past – especially in areas with high potential, such as electric vehicles. For the LEVIS project the plant in Angers, France, which specializes in busbars and electrical protection, can draw on its experience in the development of the Infini-Cell. The laminated and extremely thin single-layer busbar with inserted contacts for battery assemblies is very versatile: It connects not only the battery cells, but also monitors its temperature and voltage, prevents wiring errors and offers protection against chocks and vibrations. Infini-Cell is an important advancement toward reducing the space required for battery assemblies without compromising the efficiency or modularity of the power systems.

Knowledge transfer for the future

Besides Mersen, other partners in the project include Instituto Tecnológico de Aragón (ITA) in Spain, the CEA-Liten in France, and the Steinbeis-Europe Center of Steinbeis Innovation gGmbH (SEZ) in Germany. Together, these enterprises are advancing the research and development of innovative materials. Mersen also hopes that the project will serve as a forum for knowledge transfer with respect to innovative materials and reusability. The consortium plans to demonstrate on a large scale the technical and economic feasibility of the alternatives developed in the LEVIS project and to introduce the innovative components on the market.