Market leading cutting equipment

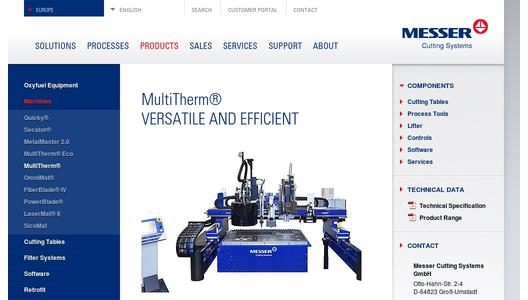

The Messer MultiTherm® is not only in name a multi-talent: the modern cutting machine combines the three processes laser cutting, plasma cutting and ink-jet marking within one nested plan. Thus, for example, internal contours can be precisely cut with the fibre laser and external contours cut fast and economically with the plasma torch. Markings, charge numbers etc. are added with the Inkjet with no damage to the material. This simplifies cataloguing the individual parts and produces advantages for traceability:

Highest quality and the most modern technology in the smallest space is offered by the MetalMaster 2.0. This cutting machine can be integrated into even the tightest spaces, requiring an area of only 30 m2. With its excellent value for money it enables even small companies to join the world of automated cutting. With its combination of Plasma and oxyfuel cutting it is suitable for a wide range of material types and thicknesses. So the MetalMaster 2.0 is not only very space saving but also operates especially economically. The MetalMaster 2.0 can be seen in action on both Messer partner stands of companies Beuting and Kjellberg in hall 13.

The points have been set for Industry 4.0

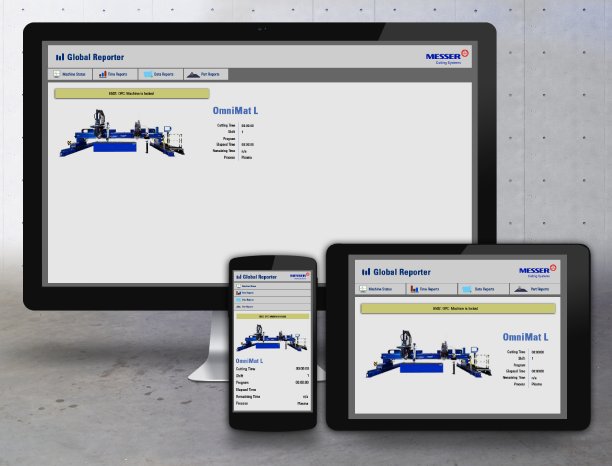

Short production cycles, the highest quality standards and increasing cost pressures demand from all branches continuous readiness to innovate, to be able to keep on keeping up with demands also in the future. A wish of many users is to be able to call up the machine status from any given location at any time, regardless of whether from PC, Tablet or Smartphone. In this way machine downtimes can be recognised immediately and corrected faster, also evaluation of the actual cutting times gives planning reliability and yields data about the general productivity of the processes. Messer Cutting Systems gives its customers the appropriate interface for this and shows in a Live-Demo how the machine data is captured with the “Global Reporter” software on their own brand control Global Control and can be displayed on a Smart Device.

Service made to measure

As customer satisfaction can no longer be achieved simply by making machine technology available, Messer has for some time been crafting an extensive service concept. At EuroBLECH Messer service experts will advise interested customers bearing in mind their individual requirements. With various combinations of the MCS service modules right up to the complete “360° All-in” worry free package you can find the optimum solution for every individual requirement. Also interested customers can get an on the spot live demonstration of the virtual service software “Remote Service 2.0”.

Further tailor made software solutions and the training offering of the company’s own training centre, the Messer Cutting Systems Academy, which is certified by the TÜV Hessen will be presented on the Messer Stand C98 in Hall 13.