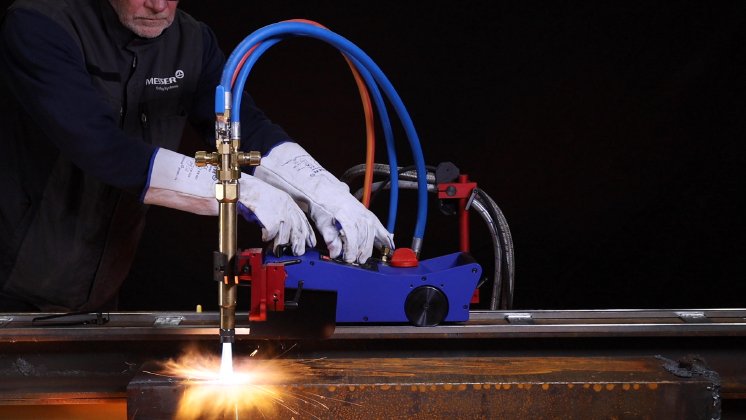

Every cutting process has its advantages and disadvantages: for example, with oxyfuel cutting greater material thicknesses can be cut, with plasma cutting higher accuracy and speeds can be achieved. The Secator 2 from Messer Cutting Systems can do both and additionally even do MIG/MAG welding, too.

Whether it is for straight cuts, curves, bevels or strips the flexible and semi-automatic processes of the hand cutting machine ensure excellent processing results and deliver an outstanding weld preparation for all applications. In doing so the powerful condenser induction motor (155 – 220 V, 50 – 60 Hz) with a power of 20 W achieves a feed rate of 0 – 150 cm/min. The speed is freely adjustable and is digitally controlled. What is more, Messer Cutting Systems also offers an optional 42 V version for special demands, for example, in shipyards. The mains plug is available for various national regions.

When oxyfuel cutting with the Secator 2, the user has various choices with respect to the type of torch and nozzle: The Secator 2 is available with one or two cutting torches for ring slot nozzles (MS 832) or for cylindrical nozzles (MS 932) or gas mixing nozzles (MSID 110-A/PMY) with fuel gases Acetylene or Propane/Methane (natural gas). The unit is available with a Propane torch for outer mixing nozzles (MSAP). Thus, a cutting range from 3 to 300 mm, or up to 600 mm When using an MSAP torch and a strip cutting width from 80 to 300 mm can be achieved. The Secator 2 equipped with one or two torches achieves a high cut quality to EN 1090-2 / ISO 9013.

With an adapter and the appropriate cutting torch, the Secator 2 is fit for plasma cutting: a combination with the Plasma Cutter 70 CT and the Plasma Cutter 125 from Messer Cutting Systems is possible here — depending upon which requirements the cutting machine should fulfil. With the Plasma Cutter 125 the Secator 2 can achieve quality cuts in Iron, Aluminium and Chrome-Nickel materials up to a material thickness of 40 mm. Parting cuts of even up to 57 mm are possible.

The third option for the precise joining of parts is supplied by the MIG/MAG welding torch for the Secator 2.

So that the cut or weld seam does not waver, the Secator 2 has available a guide rail with a length of 1.800 mm, a rack with a length of 700 mm and a trammel bar for circular cuts with radii from 240 mm up to 1.000 mm.