Anybody who wants to master the current and future challenges such as lack of skilled staff, the energy change and shortage of resources needs digital processes. Digitalisation solutions from Messer Cutting Systems network machines and systems. Thus, metalworking companies operate fast and purposefully with the aid of relevant real time information in their production. The modern solutions range from creating quotations, nesting plans and production planning right up to material handling, production monitoring and process analysis.

Messer Cutting Systems is the World-wide leader in the production of cutting technologies. As a solution supplier, the company not only offers the most modern cutting machines but is also the expert for all processes around cutting. Following the motto “Solutions beyond machines”, Messer Cutting Systems offers customised solutions using digitalisation for companies to optimise metalworking processes, improve efficiency, increase productivity, and reduce costs.

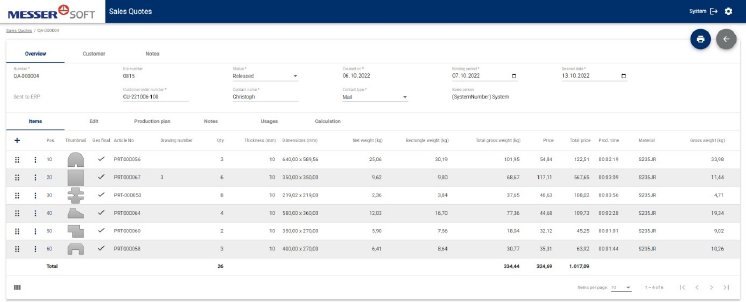

This covers all phases of production digitalisation: with the Sales Quotes module of the OmniFab Software suite, for example – linked to the ERP system – quotations are calculated quickly and reliably. These are based on the processing times, material consumption, dimensioned drawings, production parameters and many other key data. This saves time and minimises errors.

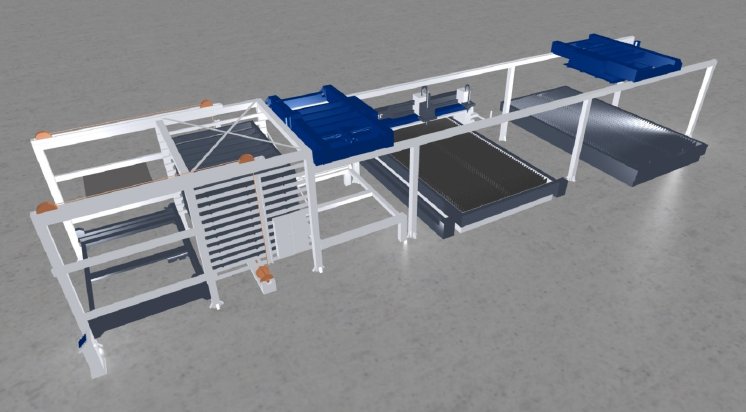

The OmniFab module Material Flow recognises exactly which cutting orders are planned for a machine at which time. It controls and coordinates the entire material flow automatically. This includes material handling systems such as loading and unloading stations, storage towers and material transport units with pallets and lifters which are fully integrated. This ensures minimum idle times.

With the process analysis tools, the production can be further optimised using real time data from every connected machine with machine loading, errors, and the causes for down-time.

Dream Team: OmniFab and Global Connect

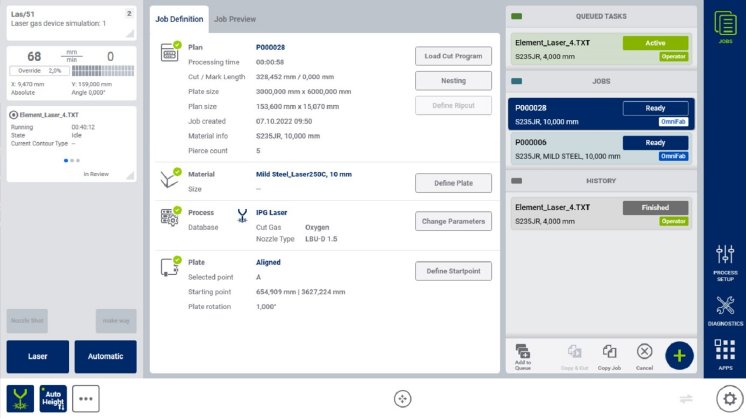

The deep integration of the OmniFab software suite in the new Global Connect control raises production processes to a new digital level. It digitalises all cutting orders and the checking of the cut parts. All cutting orders are directly available in the control ready for processing. Important information is transferred to the control pre-configured by OmniFab, even while another cutting order is just being cut.

Thanks to the nesting plans and NC programs, even complex cutting orders can be processed with high cutting quality, quickly, efficiently and with economic material usage. Digital cutting orders in production planning ensure an optimum utilisation of the machines. The cutting orders are sorted automatically according to urgency, material or other important attributes. In this way, users get the best out of their production.

The Global Connect does not only score through its modern design, but also proves to be extremely easy to operate. The operator is guided intuitively, and with tolerance for mistakes, through all production steps. Plate processing takes place without manual intervention. Reliable production data reports support an unbroken traceability chain.

The networked systems and machines from Messer Cutting Systems work together perfectly. They supply relevant information from the production in real time so that companies can operate faster, with more economy of resources and more purposfully. Thus the flexible and automated processes offer the ideal prerequisites for mastering the current and future challenges such as the lack of skilled staff, energy change, and the shortage of resources.