Stainless Steel ChallengeThe new 7000 series, MC7015, MC7025 and MP7035 have been designed to be an easy-to- choose selection of grades and chip breakers. Such is the variance in the properties and machinability of stainless steels, different tool grades matched with a suitable chipbreaker is essential to achieve reliable high volume, unmanned production. A "one grade and breaker suits all" solution is no longer the best way to realise the high rates of efficiency needed for todays demanding production environment.

3 ChoicesMC7015 is a multi layer CVD coated grade with a smooth cutting edge to prevent chip welding during higher speed, lighter cutting applications. MC7025 also has a mutli layer CVD coating, together with an optimised substrate that displays excellent plastic deformation properties. This combination of coating and substrate makes it ideal for a wide range of medium cutting applications. MP7035 is manufactured with a PVD coating for prevention of chip welding and a substrate specialised in thermal shock and fracture resistance. These properties make it the first choice for interrupted cutting and rough machining.

Easy Chipbreaker Selection

A user friendly and easy to use range of chipbreaker geometries is employed across all 3 grades.

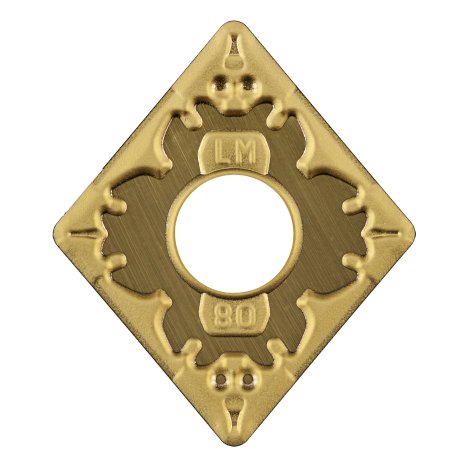

- LM breaker for light cutting provides a sharp cutting edge to drastically reduce burrs but is optimised using different rake angles around the cutting edge to also provide the necessary strength. This provides increased quality on finished components.

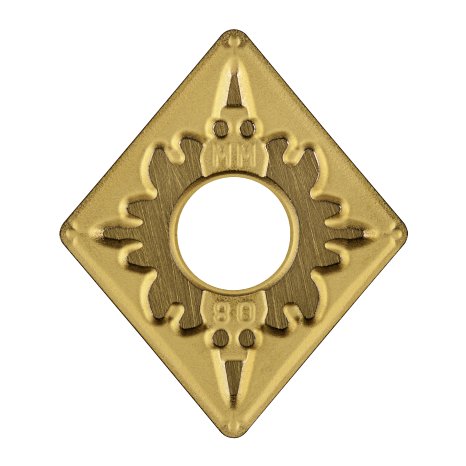

- MM breaker for the medium range of cutting has an ideal cutting edge land geometry configured using the latest simulation analysis. This has ensured control over plastic deformation that in turn leads to longer tool life and reduces the number of tool offset compensations needed during the life of a cutting edge.

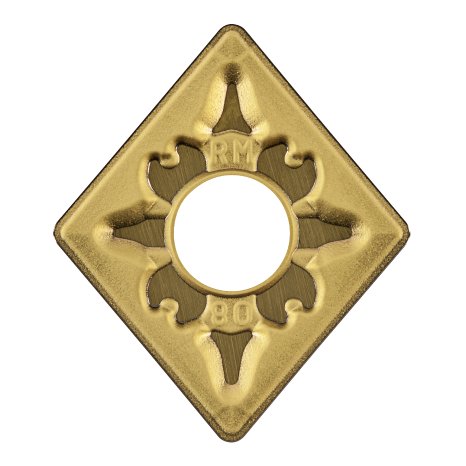

- RM breaker for rough cutting needs a very stable edge to withstand the high forces during rough and interrupted cutting. Stability is achieved by using different rake angles for the nose and flank and also has specially optimised-for-strength edge honing. The end result provides less machine down time for increased levels of productivity.

MC7015, MC7025 and MP7035 are available in a wide range of negative geometries from CNMG through to WNMG types.