Optimized, resource-sparing work process

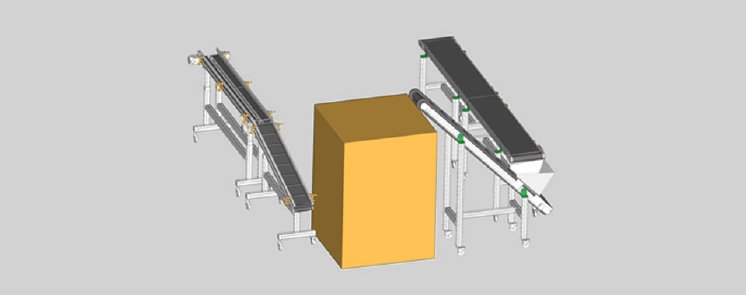

With a total of five belt conveyors – two TB40s and three TB30s – Montech AG succeeded in transforming manual into automated dry ice production. To do this, an inclined TB30 was placed directly after the dry ice block machine, which eliminates the need for a second belt conveyor or one with a bend. For the saw belt that saws up the ice blocks, the space between the two TB30s positioned next to one other was defined. And mobility was addressed by equipping all five belt conveyors with bases on rollers, which allows them to be repositioned quickly and easily if needed. And even better: The mobile base provides easy access to the processing machine and enables flexible use of the belt conveyors for different processing machines.