ReDi 1 permanently monitors the state of all system-critical operating parameters. This allows possible failures of the robust industrial computer to be detected early – before the failure of individual components – in order to initiate appropriate rectification measures. The objective is to significantly increase the reliability and so achieve high availability of the systems and to eliminate computer downtimes. During the running industrial operation, a predictive maintenance is possible that leads to a significant cost saving.

The system monitoring can cover the following parameters: the temperatures of the processor core, the housing or the hard disks, the fan speed, the state of the hard disks, the supply voltages, the redundant power packs, the display of the process data, such as CPU load or assigned memory as well as customer components, such as plug-in cards or sensors. In the event of a fault, the service technician can be notified immediately with an acoustic or optical warning signal. Furthermore, it is possible to send an alarm message as e-mail, pop-up window or SNMP.

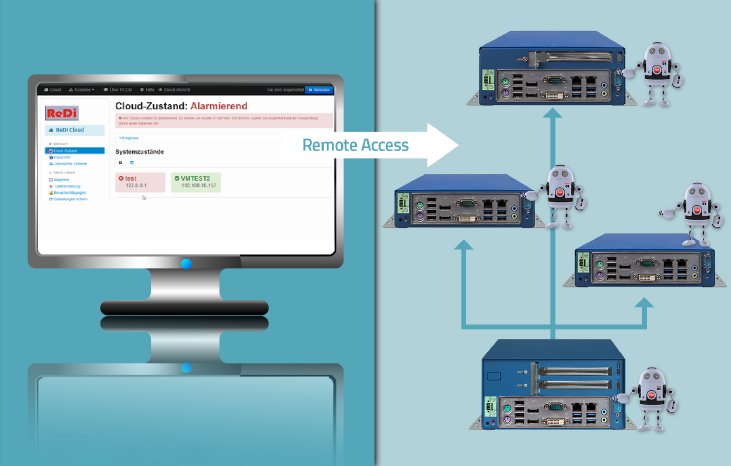

An appropriate diagnosis can be made via remote access from a Web browser (SSL/TLS-secured). As an option, the permanent monitoring of multiple computer systems in a cloud is possible.

ReDi1 is available on high-performance industrial computers based on the current 6th generation Intel® Core™ processors (previous code name Skylake). A state-oriented maintenance of industrial PCs is of particular interest in the Industry 4.0 environment for applications in the automation, medical technology, building automation, transportation and logistics areas.