The heated water can also be passed through a tube package, which usually consists of galvanized smooth tubes and leads to a cooling liquid. The heated water is passed over the cool tube surfaces and transfers waste heat to the ambient air in the cooling tower and through the pipe walls to the refrigerant in the tubes. Again, a fan blows or sucks over the tube surfaces.

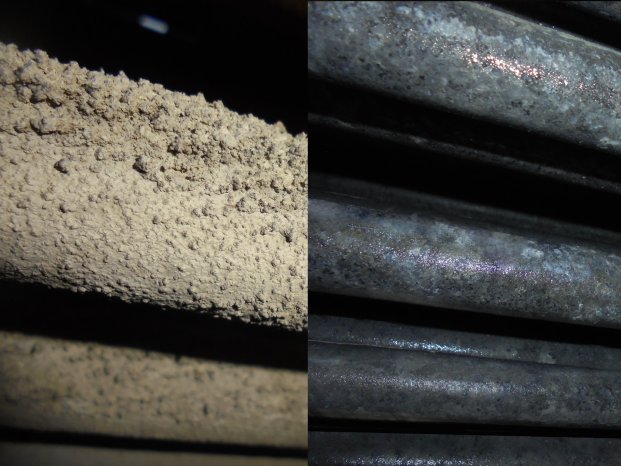

Cooling by cooling tower systems is effective and relatively inexpensive. However, soiling on the cooling surfaces reduces the cooling capacity and thus greatly increases the power consumption of the fans.

The cleanliness in the cooling tower is also important for other reasons. Above all, in the drip bodies can lead to impurities biofouling processes and thus to bacterial growth. In this case, it often creates a mucilaginous mass, which continues to grow. This can lead to the formation of dreaded Legionella. These Legionella can be discharged by the air movement of the fans or by the natural draft of the cooling tower. This can lead to serious health problems, including death.

The mostly made of plastic trickling filters are sensitive to mechanical stress. The JetMaster combination system cleans quickly, cleanly and without damage with a special nozzle attachment and low jet pressure of 4-6 bar. Every type of trickle filters are cleaned without the use of chemicals. If required, however, a disinfectant can still be used.

If possible, remove the trickling filters for cleaning. If the removal of the trickling filter is not possible due to the process or is not recommended due to a poor condition of the trickling filter, cleaning can also be carried out when installed. The special JetMaster combination system can used for cleaning trickling filter systems with a large installation depth.

Images: mycon GmbH