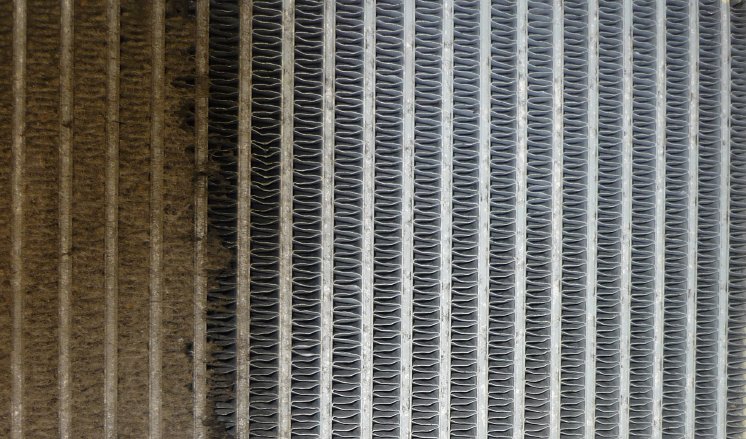

Finned heat exchangers are used in a wide variety of areas, such as in refrigerated warehouses, heat dissipation for turbines and engines, climate control for buildings, heat recovery from exhaust air and hydraulic oil cooling. They are the most frequently used systems for energy transfer. Undamaged and clean heat exchangers are prerequisite for optimal efficiency, however. Finned heat exchangers can be very easily contaminated, often by sand, dust, pollen and other particulate matter.

These contaminants form a layer that significantly reduces energy efficiency and can lead to reduced heat exchange performance. Energy costs can quickly rise by 20% or more as a result. In addition, the corrosion caused by the contaminants can result in a shorter service life of the devices. In addition to saving energy, regular cleaning is a preventive maintenance measure. Cleaning prevents corrosion and other damages, and energy efficiency is retained.

The jet stream of the new system combination from Kipp Umwelttechnik provides a stream diameter of up to one half meter. This allows even coarse contaminants to be quickly cleaned on large surfaces, as "JetPower" loosens and removes even larger quantities of residue, such as wood residues. The new system combination also uses only air and clear water without chemicals, ensuring that the environmental impact is very low.

The jet stream of the JetMaster and JetPower combination is somewhat harder than use of the JetMaster system alone. The sensitive lamella are nevertheless protectively cleaned. The proven hand test once again provides the proof: just like the JetMaster, you can easily hold your unprotected hand in the jet stream of the combination system. Both can also easily be used for automated cleaning of lamellar heat exchangers.

The "JetMaster" process, developed by Kipp Umwelttechnik together with mycon GmbH, is sold and used around the world. In addition to Germany, the process is used across Europe, in France, Belgium, Switzerland, Austria and Slovenia. In addition, the company delivers to the USA and the Near East (United Arab Emirates and Saudi Arabia). The first major presentation was recently made in the USA.

The system has already opened up a new area of application: effective, large-area cleaning of glass facades, for example, is possible without scratching or destroying the sensitive surfaces. Additional application possibilities of the system are currently in the test phase at Kipp Umwelttechnik, such as tank cleaning using special operating resources.