The problem lies in the fact that the films often do not fit the particular vessel properly. Although they shrink, they do so only to a limited extent - usually in a biaxial manner (i.e. lengthways and widthways). This means that they are only able to shrink by up to 16 percent - actually too little. They do not entirely follow the contours of the vessel, sticking out in places and wrinkling. In many cases, this negates any visual benefit they offer and can often impair the overall appearance of the packaging.

To solve this problem, Nowofol, a company based in Siegsdorf (Traunstein district) has now developed special films which shrink lengthways. Believe it or not, they can become 30 to 40 percent smaller - more than double the shrinkage compared to conventional processes. "This enables them to cope with much greater differences in geometry than previous films could," said Wolfgang Rasp, who manages the company together with Robert Hodann.

Neverbeforeseen design possibilities

Given their extraordinary shrinkage properties, these new films are perfect for use on highly unusual cans, bottles, cases and other containers. As if by magic, they cling to surfaces without wrinkling - like they were actually fixed to them. This opens up neverbeforeseen possibilities when designing containers for foodstuffs, hygiene products and detergents, printed products and the many other packaging solutions encountered nowadays. In addition, the fact that the new monoaxially oriented films are transparent rather than milky or cloudy allows them to be printed individually from behind.

As has been shown time and time again, users who are quick off the mark can gain considerable market advantages. However, it often takes time for the great promise offered by such an innovative product to come to light. This was the case with many of the innovative films developed by Nowofol. Whilst they offer compelling properties, it is only later that the groundbreaking possibilities they offer really become apparent. A widespread awareness of tradition also plays a role here. Customers are sometimes reluctant to make changes and manufacturers too have to bear this in mind. Beer crates are a typical example. They are still as widely used as ever, even though other forms of transport offer many advantages. However, anyone who is quick to seize new opportunities will usually end up a winner. Six packs, for example, only became possible as a result of suitable films and adhesive tapes for carrying handles being developed.

"NOWOPAQUE" enhances the appearance of products

"NOWOPAQUE" is another new film from Nowofol which offers considerable potential. Not only does it exhibit great opacity, it also looks totally different from all conventional films and creates an entirely different effect. Many people are surprised when they touch it for the first time. It simply feels good - not totally smooth, almost a little like velvet and slightly dry. As a result, it gives innovative packaging a special feel - a unique charm which enhances the appearance of the product considerably. At the same time, the NOWOPAQUE film is very strong. As a result, it not only looks good but also offers protection - so much so that it may be possible to do without an entire layer when producing composite materials.

NOWOPAQUE is a highly opaque film and is available in a wide range of colours. Thanks to its great opacity, the colours appear as powerful pastel shades with a silky surface sheen, creating a highquality appearance. Whilst its reduced density makes it more economical to use, it offers a high tensile modulus and tensile impact strength as well as low lengthways expansion. Thanks to its strength, it is also highly suitable for use in standing pouches which can contain anything from cat food to liquid soap. The use of particularly stiff films which are monoaxially oriented also makes it possible to increase the size of the pouches. The fact that the film tears in a parallel strip without producing a pointed edge also means that the pouches can easily be opened without the need for tools. It is also suitable for direct contact with foodstuffs.

Whether it is used with labels, as a laminating film in combination with other materials, as a selfadhesive film in packaging (tear tapes) or adhesive tapes or even for package bands, NOWOPAQUE could very well provide an additional unique selling point which makes a product stand out from its many rivals.

Trendsetters in the world of consumer goods

The managing directors at Nowofol firmly believe that innovations such as NOWOPAQUE or the monoaxially oriented film can set new trends in the world of consumer goods. They have had similar experiences with many other newly developed products since the company was set up in 1971 by the Siegsdorfbased Brückner Group (a leading manufacturer of film production equipment) and Nordwolle. It soon became clear that industrial customers often require particularly strong films or films which offer a wide range of highly specialised technical properties. The majority of these films are now firmly established on the market and have paved the way for many commercial successes.

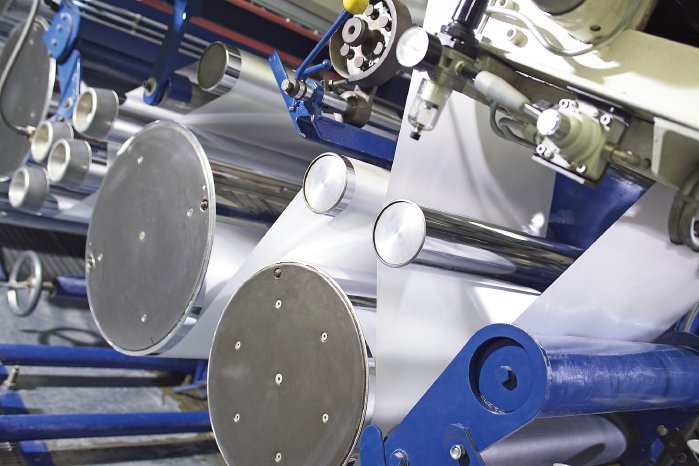

With the passage of time, the company has continuously expanded its production facilities, adding a range of new machines including some largescale types. Thanks to its latest acquisition (Nowofol's tenth production line), annual production capacity has now reached the 15,000 tonne mark. Although the film market is not only large and complex but also inundated by cheap suppliers, Nowofol has still managed to find an interesting niche for itself - as a global market leader for longitudinally (monoaxially) oriented and nonoriented flat films made from polypropylene, polyethylene and other thermoplastics. These films are referred to as "MOPP" (monooriented polypropylene film) as opposed to "BOPP" (biaxially oriented polypropylene films). They are extremely hardwearing and are used in a range of adhesive applications - an area which accounts for around 80 percent of sales.

A wide range of products on offer

The company is constantly expanding its range of solutions for the "nonadhesives market" too, adding products such as the monoaxially oriented films or NOWOPAQUE. As a result, Nowofol's films can be used in an ever increasing number of fields - from cabling and electrical applications to imaginative decor and jewellery. Its products range from highstrength adhesive tapes ("strapping"), carrying handles and tear tapes to doublesided adhesive tapes and masking tapes. Films from Nowofol ensure that refrigerator doors remain closed and butter dishes do not slip during transport. Barrels are sealed using special adhesive tapes. Thin films are even used as a separating layer when manufacturing the tails for Airbus aircraft. Particularly thick films are used to secure large components such as pipes. Compact and foamed films are used in the cable industry to bundle together cable harnesses, whilst extrastrength films are used for vacuum packaging in the food industry.

The Bavarian company's knowhow is in demand in many different countries. For example, manufacturers from the Far East are keen to work with Nowofol in demanding areas such as the production of mobile telephones, where considerable use is now made of adhesives. The films used for this purpose must possess various attributes including good stamping properties. Nowofol's specialist knowledge is increasingly in demand in the automotive industry too - another area where the use of adhesives is growing. Robotcapable technologies are important as well here. The special films category encompasses a very wide range of oriented and nonoriented films which are used to manufacture sporting articles such as tennis racquets, package bands, loudspeakers and many other items.

Film roofs for sport stadiums, zoos and shopping centres

The number of products and applications is growing all the time. Fluoropolymer films are just one of a number of areas with considerable potential. With a market share of around 50 percent, the company from Upper Bavaria is the market leader here too. The company based in Siegsdorf is the only one to offer a full range of thermoplastic fluoropolymers dominated from ethylene tetrafluoroethylene (ETFE). The entire product family is manufactured by its subsidiary company Nowoflon.

Such films are light, selfcleaning, lowmaintenance, nonflammable and hailresistant as well as highly transparent. They allow UV light to pass through virtually unhindered. This means that anyone using a swimming pool with a roof of this type in winter will become suntanned and should therefore use suntan lotion. Around 200 tonnes of the material are produced every year. This equates to around 200,000 m2 of roof or an area roughly the size of 20 football pitches.

There are around 2,000 Nowoflon roofs around the world - covering buildings ranging from large shopping centres and sport stadiums to theatres, health and beauty centres and elephant houses in zoos. Films of this type are currently being used to construct the world's largest tent for an event facility in Kazakhstan. They are also being used to roof the new Inzell Ice Stadium and even for a new threestage cable car on the Gaislachkogel mountain in the Ötztal in Austria. In this case, they will be used to roof the valley, middle and mountain stations - up to a height of 3,200 metres. The largest building with a Nowoflon film roof is the wellknown Eden Project, a botanical facility in the county of Cornwall in Southern England.

The company will be unveiling its new colour catalogue for the first time ever at the K 2010 trade fair in Düsseldorf. The colours themselves are extremely longlasting. The company even procured a weather simulator in order to carry out longterm testing on the material and colours - with all tests being passed successfully!

New opportunities for the solar market

As a result of a threeyear research project carried out in conjunction with the Bavarian Centre for Applied Energy Research (ZAE), Nowofol has participated on the development of a process which opens up entirely new possibilities for the solar market too. The company has successfully proven that ETFE films can considerably increase the efficiency of thermal solar collectors. In the absorber chambers of conventional collectors, much of the warmth obtained through converting the sun's light energy is lost. This problem is significantly reduced if the chambers are halved. However, this is possible only if extremely heatresistant films are used. The initial applications are very promising indeed.

Nowoflon ET films are also breaking new ground in the field of photovoltaic modules - devices which convert sunlight directly into electrical energy. The standard modules currently used on roofs are heavy, inflexible and immobile. They are now being replaced and complemented by newly developed modules which combine a low weight with stability and mobility. ET films from Nowoflon are used on both the front and rear sides of these highly versatile thinfilm modules. They are highly transparent, light and repel dirt. When used on the front side, they protect against wind, rain and other weather conditions. As a result, the use of heavy glass is no longer necessary. The same films are also being used to replace the intricate covers found on the rear sides of conventional photovoltaic modules. In this case, they are used in the form of lightweight, highstrength laminates. The new mobile cells featuring Nowoflon films are ideal for use on a range of uneven surfaces, e.g. pneumatic ETFEroofing elements, camper vans, etc.

Fluoropolymer films are also opening up new opportunities when used in conjunction with corona treatments which enable printing inks to adhere to plastics. For example, they can be used as "antigraffiti films" for shop windows or showcases. If such objects are vandalised by people drawing or spray painting, the films can simply be wiped clean. These transparent fluoropolymer films can be used in the same way to protect traffic signs. They are also ideal for use in many decorative applications. ET films from Nowofol can even be screenprinted.

Considerable international presence

The Nowofol group of companies currently employs 125 people. The majority of its 23 shareholders are from five families and are based in Northern Germany. Although it suffered a drop in income, the company has survived the economic and financial market crisis unscathed and without making a loss. "The company is in good health," emphasised Wolfgang Rasp. It has a sound financial basis, not least thanks to an already high level of equity (currently over 50 percent of the balancesheet total) which is increasing all the time. "We are able to take on new projects ourselves at any time," said Robert Hodann. The group's wide variety of products also gives it a certain immunity towards fluctuations in individual sectors.

Although its sales depend to a large extent on the prices of raw materials, the group expects to record significant growth in 2010, with turnover approaching €40 million. Its considerable international presence becomes clear when its sales are broken down according to regions. Germany accounts for only 13 percent of earnings, the rest of the European Union for a further 67 percent and the countries outside Europe for the remaining 20 percent. With their new products, Hodann and Rasp see attractive opportunities for expansion in Eastern Europe, Russia, Asia, South America and the USA - on top of the existing growth markets in Europe.

The company began its preparations for further expansion back in 2008. It invested around €4 million for various projects, e.g. an additional 20,000 m2 site to the north of the motorway near Siegsdorf with a view to building a fourth production plant. Great importance is attached to protecting the environment too. For example, the entire production facilities at one plant are now cooled using groundwater. This has led to a considerable reduction in the amount of electricity used.

At Nowofol, developing tailormade products is a matter of particular importance. In doing so, the company aims to provide an impetus for its customers. In many cases, working closely with various universities, e.g. the Technical Universities in Dresden and Munich, has proven useful for research and development purposes. The film specialists from Bavaria do not shy away from small orders either. However difficult a problem may seem, they are only too happy to come up with individual solutions for their customers - even if they have very unusual packaging requests.