The Ideal Combination of Rings and Travellers

Rings and travellers are the dominant elements in the ring spinning process. The key to success is the reduction of the friction coefficient to the lowest possible level. At this point you will get the perfect balanced spinning geometry, i.e. the spinning tension is on a constant balanced level. The reduction of friction will be achieved if the rings and travellers establish a symbiosis.

The aspired ideal friction stands for higher traveller speed, lower working temperature, extended ring and traveller life time, avoidance of yarn tension peaks, better yarn quality (reduction of hairiness) and reduction of end breaks. Furthermore the ideal friction strikes the balance between traveller drive angle to ring, traveller weight, traveller and ring geometry, as well as traveller and ring coating.

When using Texparts® Rings and Travellers together the perfect combination of the ideal ring and traveller has already been defined and the hub from traveller to ring is at an ideal angle. The symbiosis of Texparts® Rings and Travellers ensures a wide traveller driving angle for an increased traveller speed, less stress peaks, a reduction of end breaks and higher yarn quality due to the reduced hairiness. These advantages are the direct effect of the perfect combination of Texparts® Rings and Travellers.

Traveller Benefits

The smart traveller design with different Texparts® Traveller Coatings guarantees an optimized balance between traveller speed, life time and yarn quality. Texparts® Travellers are universally suitable and therefore no timeconsuming and complex management of different traveller types is necessary which leads to a reduction of spare parts on stock. Moreover, time is saved on every lot of traveller changes.

The Texparts® Travellers Sprint and Marathon match perfectly with the Texparts® Rings and are designed for highspeed spinning.

Ring Benefits

The Texparts® Ring Coating guarantees a longer serviceable life for ring and traveller as well as a consistent smooth running behaviour. The highest contour accuracy leads to no variations in ring sizes. Perfect roundness means no vibration during spinning. The new ring design ensures high speed spinning for all fibre materials and yarn types. Texparts® Rings are suitable for vast yarn count ranges. They are used for all standard applications and for the compact spinning process. Texparts® Rings are specially designed for a large speed range and convince by their universal suitability, excellent startup characteristics, a long service life and low traveller abrasion.

Texparts® Ring Coating

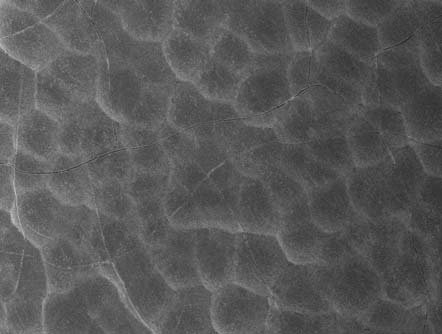

The Texparts® Ring Coating makes the Texparts® Ring so unique. The ring and traveller system in the short staple spinning process operates "dry". Fiber debris from the yarn along with natural fiber waxes like cotton pectin or spinning oil from man made fibers accumulate on the traveller/ring system. The degree and the quality of accumulation depends partly on the ring coating as well as the traveller shape and coating. The Texparts® Ring Coating Mach 1 includes the deposit function which supports the lubrication effect as well as the orange skin function to reduce the friction.

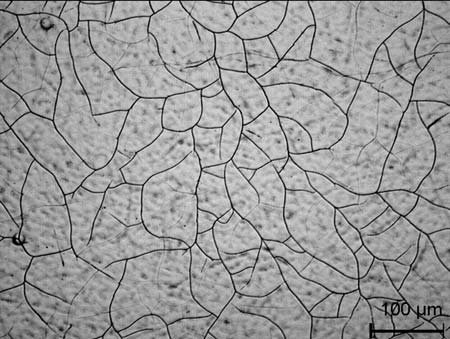

The orange skin function reduces the contact area between ring and traveller. This ensures less friction and thus an extended serviceable life.

Newest polishing technology allows the manufacturing of a defined ring surface (orange skin) which makes a runningin of the spinning rings dispensable. The microfine surface structure shows identical friction characteristics at all spinning positions of a ringspinning machine and therefore the same yarn quality can be produced on all spindles. This kind of surface ensures a quick buildup of the fibre lubrication film as well as a goods adhesion on the ring surface, even in unfavourable lubrication situations, e.g. compact yarn or core yarn.

The main goal in the development of the Texparts® Ring Coating was to extend the ring lifetime.

Texparts® Traveller Coating

Compared to conventional travellers the Texparts® Traveller Coating enables reduced runningin time. During the runningin phase of the traveller the system will be lubricated by the fibre. If the runningin time will be followed strictly the new travellers will stand out due to extended ring and traveller life time, increasing and stable yarn quality as well as end breaks at standard level. The Texparts® Traveller Coating enables a reduced runningin time compared to standard travellers.

There are two traveller types available for different speeds:

The Texparts® Traveller Coating Sprint stands for an advanced coating on a polished traveller. It is a nickelplated traveller for all standard applications. The main features are an excellent service lifetime, a smooth yarn path and good heat dissipation.

The Texparts® Traveller Coating Marathon is the special high speed coating on a polished traveller. It has a chemical deposit plating for compact yarn and for all applications in which longer lifetime is required. It offers the optimum quality for a higher performance.

Texparts® Travellers are suitable for all kind of fibre material.