Organic electronics is a platformtechnology that enables multiple applications that vary widely in terms of productspecifications. Since the technology is still in its early stage — and is in the transition fromlabscale and prototype activities to production and commercialization — it is important todevelop a common opinion about what kind of products, processes and materials will beavailable and when. The OE-A roadmap attempts to do just that.

The OE-A roadmap is a key activity of the Organic Electronics Association – theinternational key industry association for organic and printed electronics - and represents thecommon perspectives of the OE-A members.

"This second edition of the roadmap the OE-A helps the industry, government agencies andscientists plan and align their R&D activities and product plans. We will frequently updateand expand the roadmap with the international experts along the value chain,” saysWolfgang Mildner, chairman of the OE-A.

Organic Electronics Overview

Organic electronics is based on the combination of new materials – organic and inorganic — and costeffective, large area production processes that open up new fields of application. They are thin, lightweight, flexible and environmentally friendly. Organic electronics alsoenable a wide range of electrical components that can be produced and directly integrated inlow cost reeltoreel processes. Intelligent packaging, low cost RFID (radiofrequencyidentification) transponders, rollable displays, flexible solar cells, disposable diagnosticdevices or games, and printed batteries are just a few examples of promising fields ofapplication for organic and printed electronics.

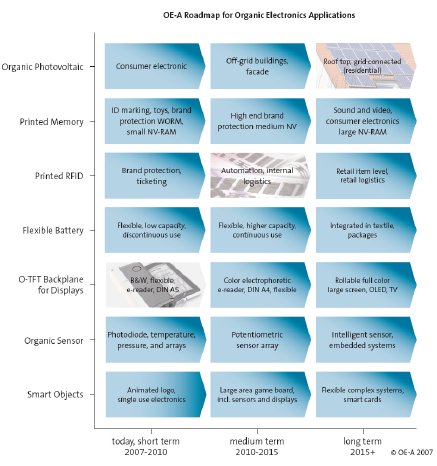

A number of key applications have been chosen to demonstrate the needs from theapplication side, identify major challenges, cross checked with the possibilities of thetechnology and to forecast a time frame for the market entry in large volumes. Key resultsare summarized in Figure 1 that illustrates the expected market entry in large volumes forseven application fields.

First organic electronics products have already reached the market, including passive IDcards, flexible lithium polymer batteries and sensor devices. Additional products, such asdisplays with organic TFT backplanes, printed radio frequency tags, organic photovoltaiccells and printed memories, are likely to reach the market later this year or early in 2008.

Within the next several years, it is expected that mass markets will be reached and that allthe above mentioned applications will be available in large volumes.

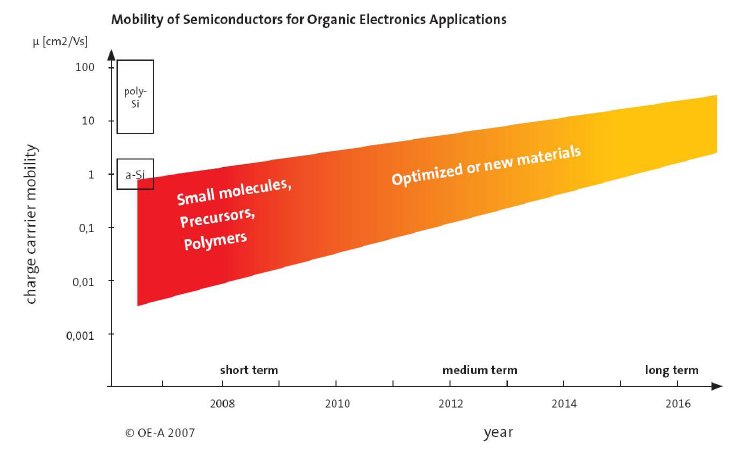

There are many approaches on the material and process side. The resulting questions – organic or inorganic, printed or not – are still under discussion. But further improvement ofmaterial, patterning processes and device design are necessary in order to meet thedemands of future product generations. In Figure 2, a forecast for the charge mobility ofsemiconductor materials for devices that are manufactured in high throughput processes isgiven. New material classes and optimized materials are necessary.