“In niche areas such as the processing of special materials — just as elsewhere — manufacturing firms expect top-quality, high-performance metalworking fluids,” says Malte Krone, Head of Product Management at Oemeta Chemische Werke GmbH. With three new metalworking fluids for carbides, non-ferrous metals and titanium alloys, Oemeta will be presenting material-compatible products with special features. For example, Novamet 1000 S is designed to offer high levels of material compatibility and corrosion protection in the processing of copper and brass. It has proven itself in a copper strip test compliant with ASTM D130. This means that plant engineers, as well as valve and pump manufacturers, now have access to a fluid which fulfils the latest requirements.

Lubricating performance improves service life

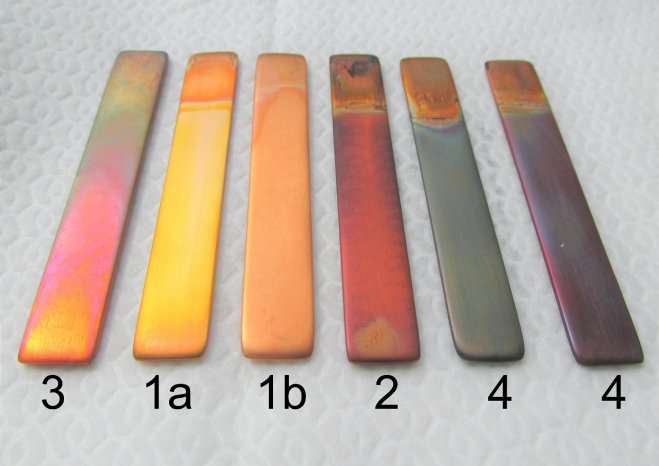

For titanium- or nickel-based alloys, such as those used for high-temperature applications or implants, Novamet 760 guarantees high lubricating performance and excellent cooling performance. “The strong lubricating performance in particular improves tool life by 20–25%,” says Krone. Machining tests carried out by the titanium working group at the PTW Darmstadt have confirmed this figure. Novamet 760 is designed for use in aviation, in the automotive industry and in medical engineering.

Outstanding swarf removal for carbides is guaranteed by Oemetol 605 HM. This special product was developed on the basis of a GTL oil and offers excellent cleaning performance, preventing grinding burn during tool manufacture, for example when grinding carbide cutters. It also prevents cobalt from being released from the grinding sludge.

Manufacturer with a wealth of experience

Oemeta will also be using the world’s largest international exhibition for metalworking as an opportunity to highlight its expertise via customer feedback, empirical values and research findings. Oemeta at the AMB: hall 8, stand C70, and at the stand of PTW Darmstadt, hall 10, stand E51.