The extensions and innovations presented in hyperMILL® are extremely versatile, including form contour compensation for gentle movements during abrupt changes in direction, the hyperMAXX® module for high-performance roughing with dynamic feedrate adjustment, and various special applications. One highlight is the new 'Rib Milling' cycle. OPEN MIND worked together with one of Germany's largest automotive manufacturer to develop this cycle for programming negative rib shapes. This feature automatically detects grooves to be milled, and steep areas and floors are machined separately.

Module with a profile

Another module with great optimisation potential is the tyre module, which speeds up the process of manufacturing tyre moulds. It features a new Tire Browser, which is completely integrated in hyperMILL®. The tyre clock component of the Tire Browser contains all relevant tyre design information (segment, tracks, pitch sequence, pitches).

CAD for CAM users

"Alongside a range of optimisations and our brand-new hyperCAD®-S core, Version 2013 stands out due to the fact that we achieved a complete synergy between CAM and CAD for the very first time", says Dr Josef Koch, CTO at OPEN MIND Technologies AG.

hyperCAD®-S has been developed from scratch, so the architecture, core, graphics, database, user interface and API are all newly designed and coded. The specifically developed hyperCAD®-S core ideally supports imported data. Users have the advantage of being able to easily modify any of the geometry elements at any time. Curves and free-form surfaces are depicted using Bezier and NURBS geometries. In addition to the familiar basic elements for construction, the core now also provides a number of elements that specifically aid CAM programmers, including tool paths, polygon networks, point clouds and a rectangle element.

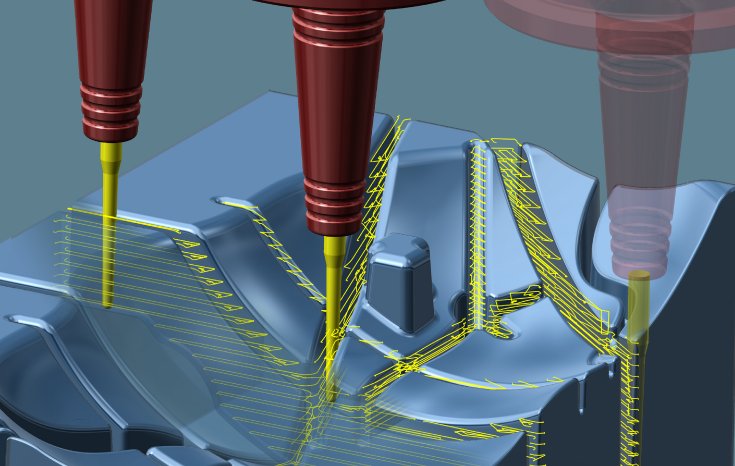

hyperMAXX®

The dynamic feedrate adjustment of the hyperMAXX® high-performance cutting module for hyperMILL® reduces milling times, increases tool life and prolongs machine life. This is accomplished by preventing sharp edges or sudden changes in milling direction. hyperMAXX® is now available for 2D pocket milling, 3D arbitrary stock roughing and 5axis shape offset roughing.