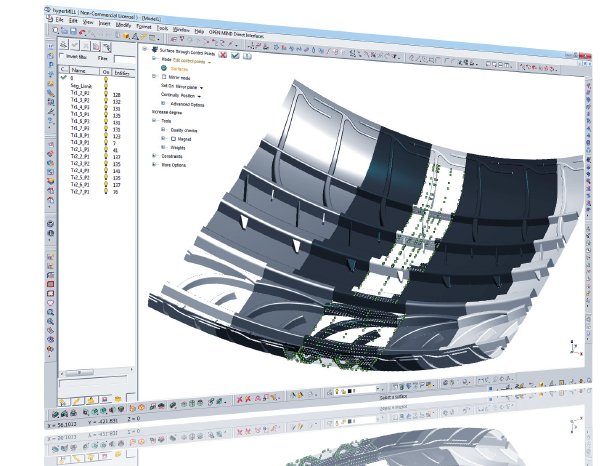

The tire module features a new 'Tire Browser', which is completely integrated in hyperMILL®. It allows you to simply and quickly edit and create tire definitions. Here, you can clearly manage all pitch geometries, for example.

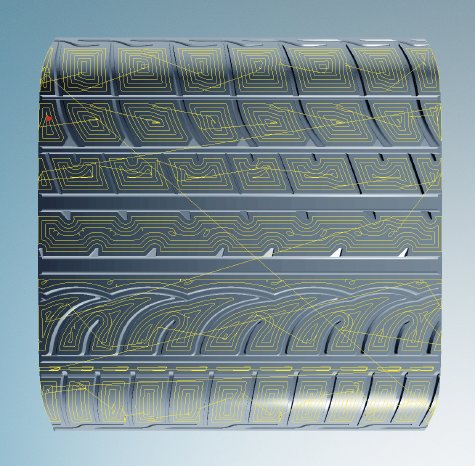

The tire's design is defined in the 'Tire Clock' with all segments, tracks, pitch sequences, pitches. Once the pitch geometry has been defined, automated functions support creating and managing the elements and geometries required for programming. The user can display the suitable geometry for each operation in order to avoid errors. This means that each pitch only has to be programmed once. The new 'Multiple Track Support' function allows a separate pitch sequence to be defined for each track.

Tire-specific 5axis strategies

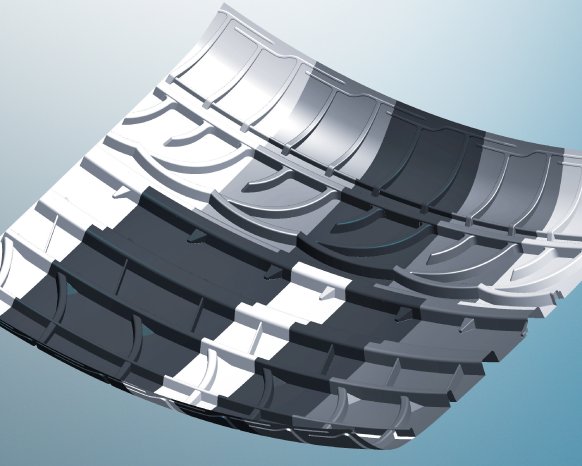

hyperMILL® tire module provides optimal support all the way from defining tire geometries right through to production of the segment tool. It is possible to automatically generate segment surface geometries with trimmed splits. Automatic segment program generation handles trimming, sorting and linking tool paths - including collision monitoring - for process reliability. Unnecessary movements can be eliminated by trimming the toolpaths at the segment limits. hyperMILL® offers a range of specific 5axis strategies to machine curved surfaces with a consistent offset in a quick and simple manner.

![tire_e[1].jpg](https://cdn.pressebox.de/r/aca163995e05d040/attachments/63/92/22/thumbnail_639222_746x466.jpg)