With their comprehensive CAM concept, including innovative postprocessor technologies, OPEN MIND Technologies AG promises the highest efficiency and precision in the machining of moulds and components. OPEN MIND’s focus at this year’s METAV is on the new Version 9.7 of hyperMILL®, one of the most modern CAM programming environments on the market for fast, flexible and cost-efficient machining. With its intuitive user interface, the hyperMILL® CAM solution offers users a wide range of machining strategies for 2D, 3D, HSC, 5-axis and mill-turn projects.

"Especially in complex 5-axis programming or combined milling and turning jobs in a single set-up, you can really see the advantages of the perfectly tuned machining cycles and their automated functions. They allow the user to easily program complex NC machining operations," says Ines Kaminzky, PR Manager at OPEN MIND. "We are showing METAV visitors that hyperMILL® Version 9.7 is a professional tool that enables seamless programming of complete machining solutions with maximum precision, efficiency and dependability."

Seamless, integrated programming...

The essential foundations of hyperMILL®’s automatic programming are the feature and macro technologies. Integrated automatic feature recognition makes CAD-rendered geometry data fully utilised in CAM programming. In solid and surface models, the automatic feature recognition capability recognizes geometries such as holes, threaded and unthreaded drilled holes, as well as open and closed pockets. This process automatically generates the parameters required for programming and tool selection.

The macro technology in hyperMILL® enables the combination of machining strategies and tools with these features. The macro database creates a well-organized storage environment for macros, and the database contents are made comprehensible for every user by means of comments and graphics that are stored within each macro.

hyperMILL® can also be used as an integrated CAM solution for leading CAD applications. For example, hyperMILL® for SolidWorks®, which received Gold Certification for its perfect integration, quality and interoperability, as well as the integrations for Autodesk® Inventor™, thinkdesign® and Pro/ENGINEER® Wildfire™. The OPEN MIND solution allows the creation of integrated process chains for all current CAD application users.

... and reliable milling

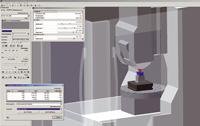

With the workspace monitoring feature, the user can determine in advance, based on the stored machine model, whether the machining operation is feasible within the workspace or if a limit switch will be traversed. The unique Best-Fit function automatically optimises the machining operation to match the available workspace. This allows the best possible space utilisation, even with small-scale or limited-function machines. Furthermore, the machining and material removal simulation enables a collision check, down to the smallest detail.

OPEN MIND’s industry leading postprocessors are adapted to a wide spectrum of machines, controllers and workflows, ensuring that the CAM programs will be perfectly executed on the machine.

For more information, visit www.openmind-tech.com or visit OPEN MIND Technologies at METAV 2008 in Hall 3, Booth D63.