hyperMILL® 2011 offers new functions that help you achieve simple, user-friendly and time-saving workflows. A proven technology for intelligent macros was extended for this purpose. Users can now save predefined rules and conditions for every stage of the machining process in the CAM software, which is made in Germany. hyperMILL® automatically assigns and adjusts the job steps to the corresponding geometry based on these rules and depending on geometry information such as diameter, depth, open or closed pockets. Application programming interfaces (APIs) provide further automation support: They can be used to create applications that control the generation of complete NC programs.

Optimal 5axis machining

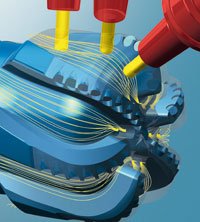

New functions and optimised strategies further lower the programming burden and help to obtain better milling results. The new contour offset roughing and finishing function offers a strategy for the 5axis machining of surfaces with a uniform offset, while avoiding the formation of 'steps'. hyperMILL®'s automatic 5axis approach and retract strategies improve machining safety and quality. Improved 5axis swarf cutting results in better surface quality.

hyperMILL® offers alternative manufacturing methods by exploiting the options for 5axis machining with innovative technologies and reducing processing times in complete machining in a single step.

64-bit support brings further time savings

64-bit support means that users have more memory at their disposal. This means that many calculations can be carried out considerably faster. These features are especially useful when machining large models, which require a large number of job steps and toolpaths. hyperMILL® users thus benefit from further time savings in their day-to-day work.