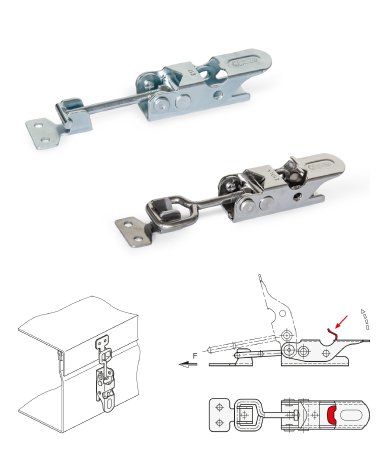

Made of zinc plated steel or stainless steel, they are designed with holding forces of 1000, 2000 and 3000 newtons and supplied with a loop-shaped or T-shaped latch bolt. The new toggle latches of series GN 761 close the gap between the heavy and light duty designs of these Ganter standard parts, offering the perfect solution for nearly every situation. Wherever flaps, lids, covers or hoods must be closed quickly, easily and reliably, these robust toggle clamps are the ideal choice. They can even be secured with padlocks. The thread on the latch bolt allows for simple adjustment of the travel distance to ensure precise actuation of the lever.

Along with the two latch bolt types described in the standard sheet, the T-hole and loop, Ganter also offers the option of other custom designs with regard to dimensions, shapes and features. For example, latch bolts could be fitted with an integrated spring to compensate for tolerances or elastomer inserts could be used in situations where the latch bolt and the catch do not line up.

Ganter is continually expanding the new toggle clamp series with a more secure version: On the GN 761.1, the safety hook integrated into the body automatically latches into the actuating lever at the end of the closing movement.

This ensures that the toggle clamp remains reliably closed and will not open accidentally. The clamp can only be opened after unlocking the safety hook. This can be done with just a single hand and as always Ganter is focused on user-friendly operation and has already provided for customer specific and application specific aduses in the initial design.

More information on Ganter standard parts can be found in the internet at: www.ganternorm.com