Hall: 4, Stand number: D 11

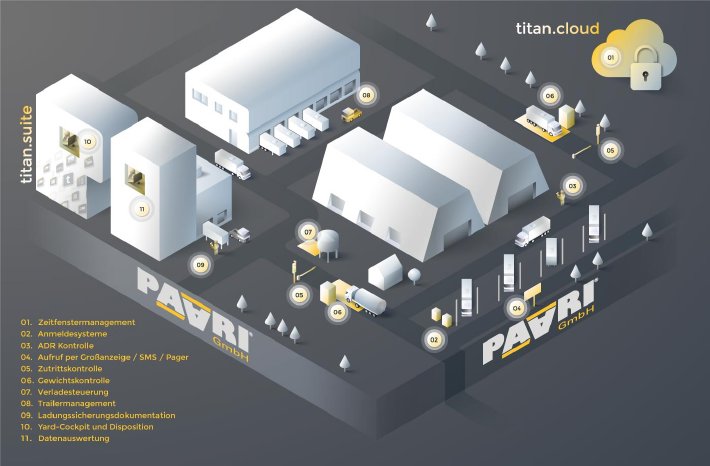

LogiMAT 2025, 11.03.-13.03.2025 in Stuttgart - As an international company from Thuringia, PAARI will be presenting its innovative products and services for its solutions in yard management and the automation of weighing processes at this year's LogiMAT logistics trade fair, demonstrating how the optimisation of logistics processes on the factory floor increases the overall effectiveness of companies. PAARI focuses on three things in particular: digitalisation, progress and sustainability. At LogiMAT 2025, PAARI will be showcasing the latest developments of its in-house software suite titan with new innovative solutions such as material flow management and trailer management. The company will also be presenting the next generation of its self-service terminals in a new, modern design with familiar intuitive user guidance. PAARI will be exhibiting in Hall 4 at Stand 4D11.

In the age of digitalisation, an efficient and automated system that can record and control the material flows of incoming and outgoing goods plays a major role. PAARI's smart yard management system solutions make a decisive contribution to process optimisation and take the entire process chain into account right from the start.

Transparency and trust through digitalisation

PAARI's solutions provide precise and collaborative time slot management right from the preplanning stage. When a lorry rolls onto the company premises, the driver no longer has to spend a long time searching for the loading or unloading point intended for him. They can log on to a multilingual PAARI self-service terminal using their order or time slot number on the touch monitor. PAARI's registration terminals enable a digital check-in process which, in addition to secure and efficient registration and deregistration of lorries on the factory premises, also offers the possibility of carrying out instructions, driver briefings or dangerous goods checks directly and digitally, for example, thus saving a massive amount of time. If necessary, safety training can be completed in advance - for example, before the rest periods are observed or before the start of the journey the day before. This means that throughput times at the plant can be further reduced. Language barriers, which are still often a problem in communication between logistics staff and lorry drivers, are also a thing of the past thanks to the multilingual self-service terminals. The customer-specific operating processes now decide whether the truck driver waits to be called by smartphone or large display after registering in the car park or gains access to the company premises by scanning a barcode from his order papers or RFID card. Modern truck scales with self-weighing also provide the necessary control of incoming and outgoing lorries. Loading documentation can be carried out via camera systems, light barriers, traffic light systems or access systems. After successful loading or unloading, the lorry drives onto the scales again, receives its weighing slip at the terminal, taking into account the eANV verification, and leaves the factory premises. The subsequent delivery note and invoice are generated using various modules from the titan software suite. PAARI is also a pioneer when it comes to the digital creation of delivery notes and their integration into the fulfilment process. By optimising the flow of processes in the yard, even use of resources can be ensured, peak loads can be avoided and waiting times and throughput times can be significantly reduced.

Many years of experience in the hardware sector

In addition to innovative software, PAARI also has decades of experience in the field of hardware. This expertise enables the company to offer both sophisticated standard systems and highly customisable solutions that meet individual customer requirements. The combination of advanced hardware and intelligent software results in a system that is convincing in all areas of yard and factory logistics.

The versatile self-service terminals (SBT) are manufactured in-house and will be given a new, modern design in future, which will be presented for the first time at LogiMAT 2025. The triedand-tested standardised PAARI installation kits, which can be exchanged via plug-and-play, will be retained. Nevertheless, new features will also be added, true to the motto: Functional. Beautiful. Colourful. Depending on the intended use of the terminal, different types with different features are available.

Hybrid systems for maximum flexibility

PAARI has set itself the task of perfecting its customers' logistics processes with the help of its numerous modular plant logistics solutions. With its hybrid approach, PAARI combines the advantages of digital technologies with tried-and-tested processes. The combination of onpremise software and web apps unites the best of both worlds and enables flexible and powerful utilisation of the technology. The applications in the local language ensure that operation is intuitive and barrier-free. This innovative mix contributes to seamless integration into existing logistics processes and emphasises the solution's high innovation factor. Thanks to the flexibility of the hybrid systems, PAARI can support both small and large companies individually and adapt seamlessly to their respective needs. The hybrid structure of Yard Management also makes it possible to utilise existing infrastructure effectively while benefiting from the advantages of new technologies. This reduces implementation costs without compromising on performance.

Advantages of PAARI solutions at a glance

1. time-optimised process chain design ensures efficient loading

2. seamless tracking of lorry movements provides more security

3. reduction of language barriers through multilingual registration terminal 4. cost savings by reducing the waiting and dwell time of lorries

5. contribution to sustainability through digitalisation

6. real-time information for management and systems for more transparency