As a solution provider for sewing and welding covers, shift levers and filters, the company has risen to become the premium address in the industry in the last two years and is now a vital partner of the automotive industry. The developments are designed and realised in dialogue with the customer. Everything is planned in detail together with the customer up to initial commissioning and the production start. PFAFF INDUSTRIAL has also adapted to the strict guidelines in this industry's service area. The company is currently in the launch phase for a large-area sewing unit PFAFF PORTAL (sewing area of 1200 x 700 mm).

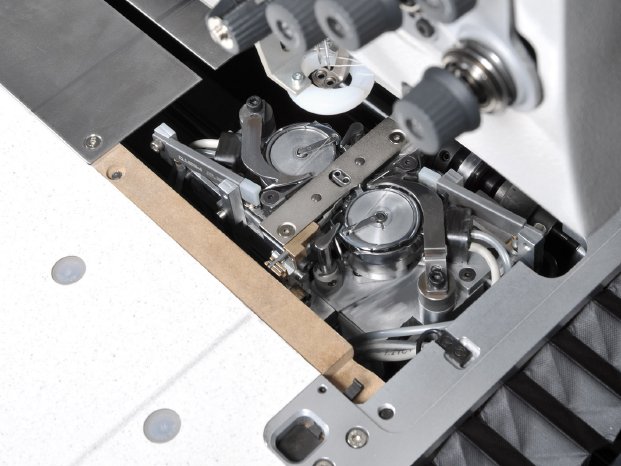

Process reliability and repeatability are crucial criteria for the automotive industry. The new PFAFF PORTAL combines sewing process reliability and seam quality in a unique manner. The latest generation of large-area sewing unit are powerful machines that are "Made in Germany". Know-how and experience paired with the latest technologies in mechanical engineering and drive and control technology set the standards in reliability and process safety. The sophisticated sewing technology based on a unique seam optimisation system ensures a suberb seam quality and a perfect stitch pattern in multi-directional sewing operation. The new PFAFF PORTAL enables complex top-stitching and ornamental seam work to be performed (One- and two-needle operations). These types of visible seams on the car interior define premium quality for car manufacturers. The market launch of the Portal in Europe has been very successful. PFAFF Industrial is in close contact with customers in Asia and the Americas. The first machine is currently being installed at the production facility of a renowned manufactured overseas.